Fun watch related to your pic https://youtu.be/udNXMAflbU8

Mildly Interesting

This is for strictly mildly interesting material. If it's too interesting, it doesn't belong. If it's not interesting, it doesn't belong.

This is obviously an objective criteria, so the mods are always right. Or maybe mildly right? Ahh.. what do we know?

Just post some stuff and don't spam.

Fuck yeah, technology connections.

I knew it would be before I clicked. Alec is great!

summary: the holes are almost never (purposely) used to secure the plug in the socket. it is often just for manufacturing reasons (but not always, as in this case). it is included in the specifications as an optional feature, so that the holes are not made too big, or in the wrong place.

I’m curious why he doesn’t talk about all the patents that specify locking as a feature. Even modern patents reference the features of older ones in their designs if they use them.

He used all modern plugs you would find on houses in 2000+, of course none of them lock the old way. Go grab some from the 20s and 30s.

In the cheap one, we have two perfectly flat brass pieces pressing against each other.

I'll bet you any ammount you want, that's not brass. It's iron with brass coating.

Is a brass coating not, technically, a flat brass piece pressed against another?

Here is an alternative Piped link(s):

https://piped.video/udNXMAflbU8

Piped is a privacy-respecting open-source alternative frontend to YouTube.

I'm open-source; check me out at GitHub.

I knew exactly what video you linked before I clicked it.

I am very familiar with Alec. Love that channel.

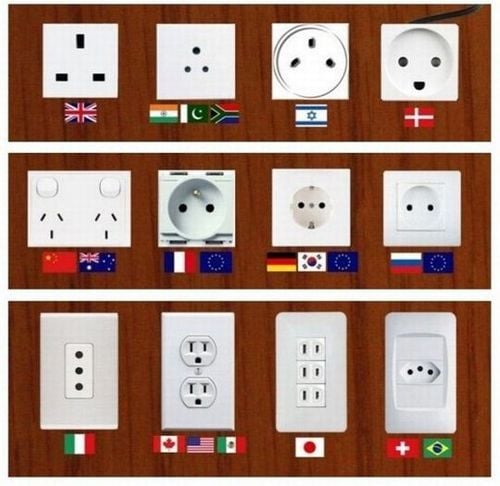

I'm not American, but I've lived a few years in the US. I find it very interesting that the US invented the electric infrastructure that we use today, but they really screwed up a few things. Firstly, the connectors are far too unsafe. They are flimsy and have no protection from electrocution. Secondly, by using 120V as the main voltage, you need more current to do the same amount of work as a 240V system. Thay means thicker wires, more stress on the plugs, and greater fire hazards.

Shuko plugs FTW

Common misconception about the voltage though, the US does have a 240v system (well in houses, some places have three phase power which gets weird). The breakers can be wired to give 120v or 240v. The large appliances like driers or electric car chargers and things that do need a large ampunt of current get wired up for that. It's really only a slightly slower electric kettle to deal with as a minor inconvenience. Or maybe if you wanted an absolutely enormous electric space heater or something, but those are dangerous as it is. Not a lot of things used need more than the 1800 watt maximum. As far as I can tell it's just a relic of history, Edison ran his generators at about 110v originally and that's the voltage original light bulb filaments wanted and higher voltage filaments weren't used until after the US had already been electrifying to a good extent. Theoretically 120v might be a little safer from a getting shocked standpoint, but electrocutions are pretty rare as it is, just a historical artifact and not a conscious design choice as far as I can tell (and yes, volts do matter too, not just amps. Especially if what's being shocked has very high resistance, like human skin).

Technology connections has a fun video on this too in addition to the plug hole video someone linked elsewhere: https://youtu.be/jMmUoZh3Hq4?si=4a1SCYOZUy-1z2h_

I've used electric kettles in the US and Europe and they're barely slower. I think the difference is overstated. It's often used as the reason that fewer Americans have kettles but I think the real reason is just that Americans drink fewer hot beverages other than coffee, and most people have a machine for that.

While 120v is safer for shocks I think the greater safety reason for 240 is lower fire risk which is more common and dangerous that shocks in either system.

It's not surprising. If you're first to adopt something by the time you realize how it could be improved you're locked into what you did. It happens with all kinds of early adoption. I noticed it a lot in Japan which picks up tech really quickly but as a result has been left with a bunch of crufty old systems. Like they were way ahead on contactless payment, but now they have a bunch of complex and confusion payment systems and lots of them don't support credit cards while the rest of the world just has contactless credit cards.

yeah but it looks like a funny face!

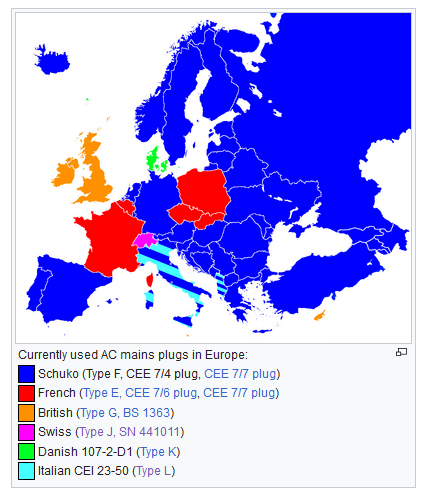

I didn't know that schuko plugs are the norm for most Europe countries, I thought it was a German thing

https://en.wikipedia.org/wiki/Schuko

Also the french system is compatible with Schuko, so that makes it even more universal.

I feel like the US has a very strong resistance to change regarding standards.

The 110v for example used to be the norme in France, but they changed it to 220v in the 50' and then 230v in the 90'.

Same thing for the plugs, the paper size, the measurement system ...

I think "US doesn't use the metric system" is really overblown. Sure some common things like miles and weights and cooking that people use every day are still done with standard units. But you could say that about many other countries that are "officially" on the metric system. You can't really force people to stop using units they're familiar with. Any product I can think of in America is required to have both metric and standard units labeling it. Technical fields like science and medicine don't touch standard units, would be ridiculous. All metric. If you tell your doctor your weight in lbs it's instantly converted to kg and that's what's used in the system (dosing is done in mg per kg bodyweight often). Every kid in America learns how to use the metric system in school. Construction is probably the big place where it still gets iffy, but even then you can easily get metric or standard bits and things like that. Like what do people want to say we've "converted?" Slap all the current cooking/measuring cups out of people's hands that say both mls and cups, saying no how dare you use cups to measure out the water for your recipe, here have a measuring cup with only mL labeled instead, you're welcome.

Also ripping out and replacing the entire electrical system of every building in the United States, and scrapping every 120v electrical appliance in the entire country, seems like it would be horrifically expensive and wasteful for some very minor benefits. Maybe a switch could have been made early on in the development of the electrical system, but that ship has sailed. And you can wire up outlets in America for 240v plugs too, the breakers let you do both. So if you need more current for your clothes drier or another large appliance for instance it can be done.

Standard is alive and well in engineering and architecture. We have slugs as a unit. g is ~32ft/s^2 and buildings have feet.

Many people from other countries fret about the unsafe plugs in the US. They of course do not have the same level of safety, but it also doesn't appear to matter. I have never been shocked inserting or removing a US plug. I don't know and haven't heard of anyone who has. People do get shocked, but for other reasons.

I have, but I was a child and very much not plugging it in the right way. It was in a very cramped space I couldn't see, and dumbass me thought holding the metal would give me better control. It did, I made it into the plug.

Ok, so there are people out there doing it.

Type J > Shuko

Type J is safe and a better implementation. I don't know why the EU didn't choose type J as a standard.

It cant plug both ways

Americans plugs are very strange

European plugs are too big and bulky for our liking.

The holes are only for manufacturability.

Older receptacles had a design that would hug the holes to hold the plug in place. It’s a holdover for people with older houses.

I think this fact is actually a myth, the holes are for manufacturing as stated previously.

Not exactly a myth, but likely never used for retention purposes as was originally intended. See more here: https://electronics.stackexchange.com/questions/11495/nema-5-15p-blade-holes

https://youtu.be/udNXMAflbU8?si=vKhkE-pKhltLJ_dF

Not all of them do.

This is the first thing that came to mind. If you didn't link it, I was lol. I love this channel.

I always thought the holes were there for OSHA lockout/tagout locks.

They are a byproduct of the manufacturing process. There's a Technology Connections video about it that I'm too lazy to lookup on my phone.

Technology connections got it wrong. The oldest receptacle he used was from the 2000s. He also didn’t do any research. Modern manufactures keep doing it for the all the old receptacles out there. It’s why the hole size IS specified by NEMA if you are going to include them.

Theres plenty of patents that specify the locking function, and even some modern patents refer to those old locking features with their features.

I was bored enough to look up the link

https://www.youtube.com/watch?v=udNXMAflbU8

Here is an alternative Piped link(s):

https://www.piped.video/watch?v=udNXMAflbU8

Piped is a privacy-respecting open-source alternative frontend to YouTube.

I'm open-source; check me out at GitHub.