This one is still a work in progress, I'm hoping to have all the finish work done by next month. I probably won't get the lighting and stereo and all that installed until the end of the summer. I'm hoping this can be a hangout spot for them and their friends after they outgrow the slide. The huge roof is kind of the keystone of the whole thing. I've driven past hundreds of backyard playhouses and I've never observed a kid actually playing on one of them. I think a large part of it is because once you're done with the built-in toys, it's just not that fun anymore. Plus it's hot as hell under there, even in the shade. I noticed my covered deck is pretty nice and chill even on a hot day due to having a real roof overhead so I wanted to put the same thing over the playhouse. This thing isn't a play set, it's more of an outdoor space where they can hang out, craft, paint, read, play, build, and have their own place to do their own thing. So far they've been out there almost constantly.

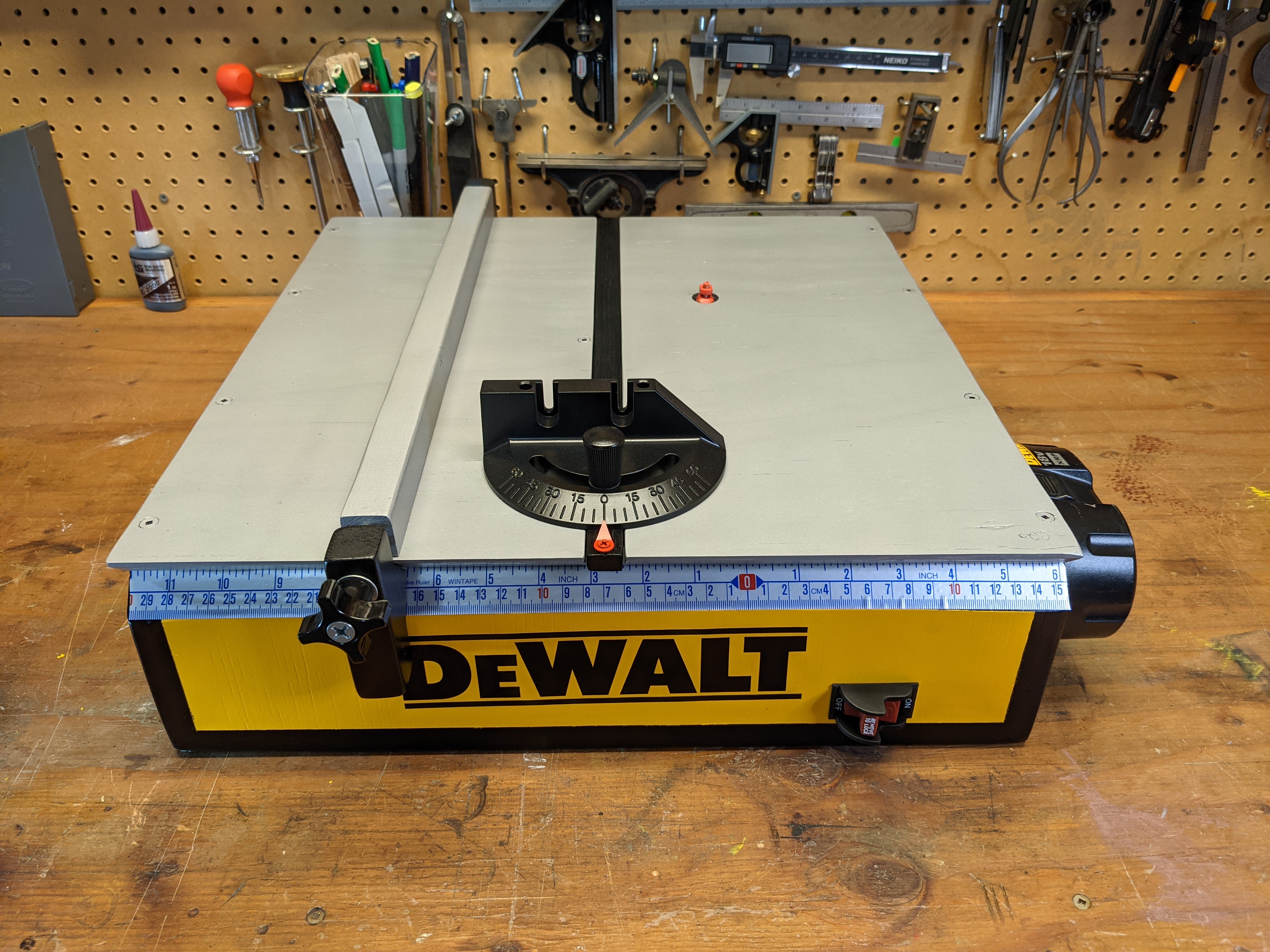

Here's the sketchup model I made. It's my first project using CAD instead of scribbling on notepads and offcuts but it has been extremely helpful and I will definitely be using it again.

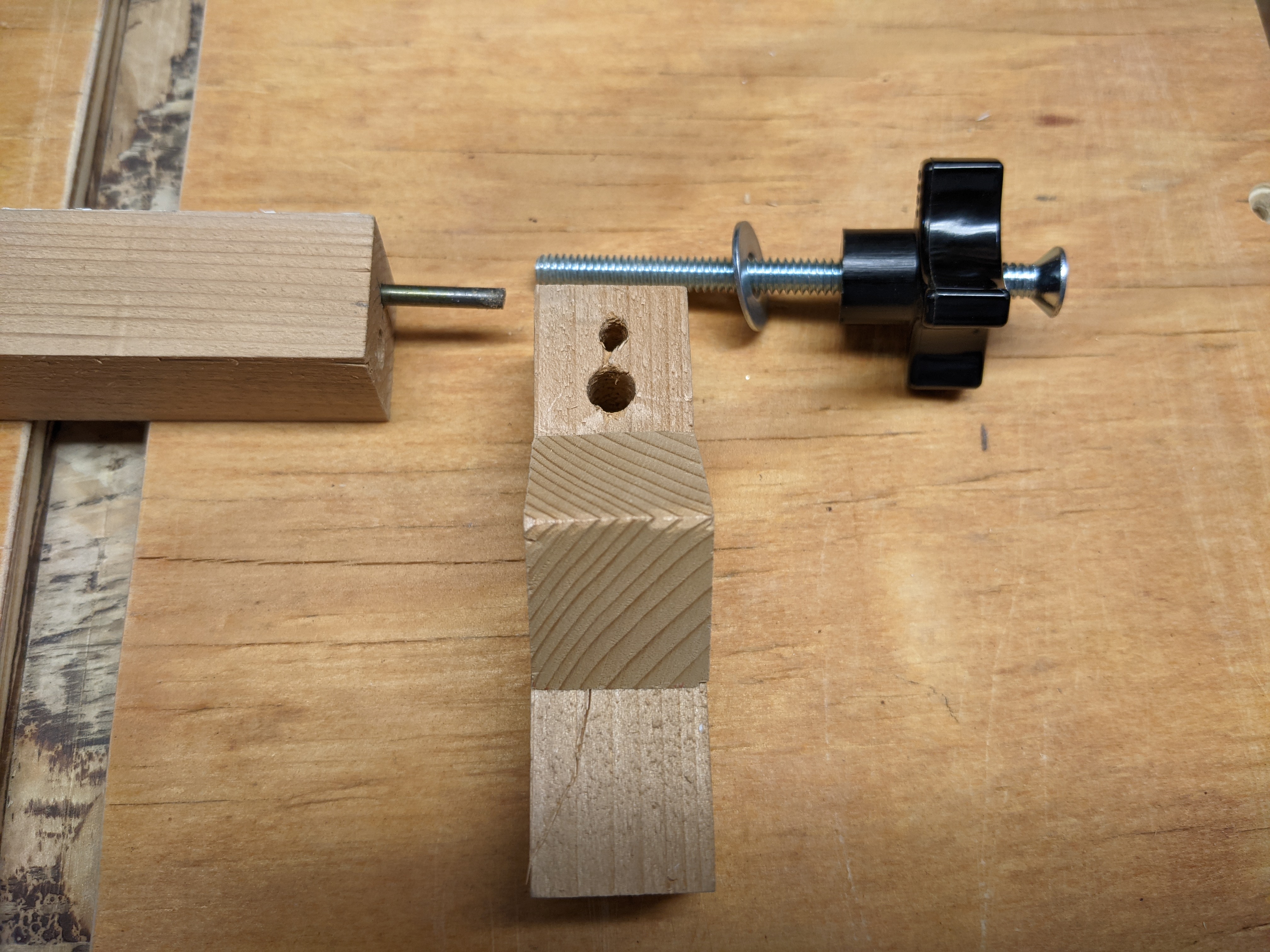

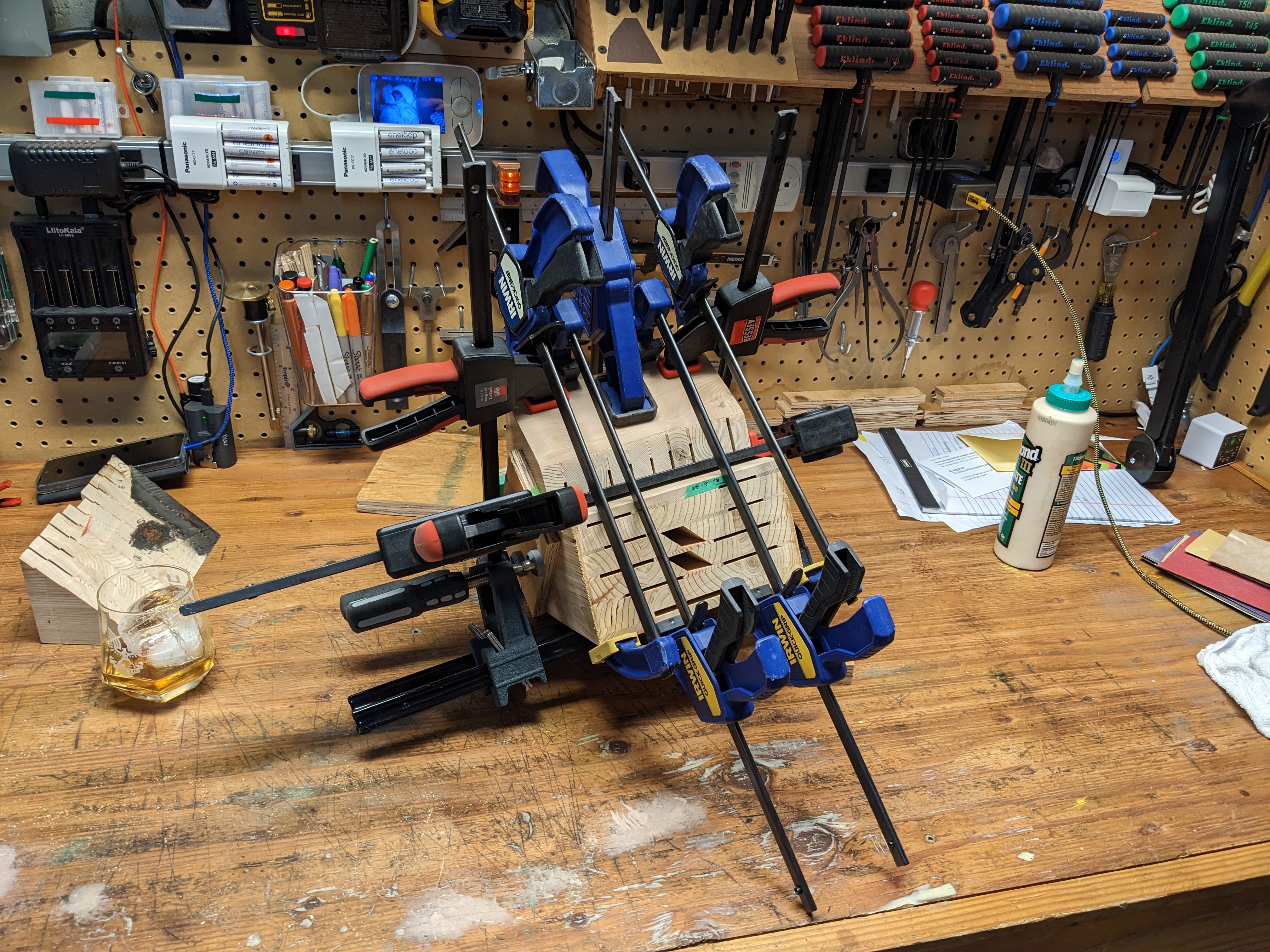

I got most of the framing done last fall. The basic frame sits on 14"x48" rebar reinforced footings. The posts are 6x6x10, and all joists are 2x8. The joist hangers are attached to tripled 2x10s. This thing is built like a fortress.

It sat idle over the winter but as soon as the weather was nice I got back at it, there's a ton of finish work to do. My daughter said she wanted a garage and a workbench just like mine so I got right on that! It's the first picture up above.

Here's the original one. Back in 2018 we decided it was time to get a playset for the little one. I looked around and thought "There's no way these things are worth $1000-$2000! I better get a used one and save some money." So we found one on a buy/sell/trade site for $100, took it down, and brought it home. Upon trying to set it back up I realized half the boards were rotten. I had a bunch of used deck boards from when I replaced my rotten deck, and I kept the very best looking ones for a future project such as this. Unfortunately I missed a small rotten core somewhere and one of the main structural members rotted out after less than 3 years. So for Round 2 I figured it was time to go big or go home. Just for materials it's going to end up being 4x more than if I'd just bought one brand new the first time around, but I think they're going to get way more enjoyment out of this one.

Had mine done almost 18 years ago and absolutely 0 regrets. One eye went from 20/200 to better than 20/20. The other wasn't as bad and was corrected to be 20/15. Vision has not regressed at all in either eye. Dryness was mild at first but completely recovered after several months. I've had no halos or night vision problems. The most important thing to remember is that not all procedures are equal, and not all clinics are either. Go to a few different eye doctors and ask who is the best in town, and then go there. Don't get quotes, don't shop for coupons, and don't go with the 2nd lowest bidder. If you can't afford what the best surgeons in town are charging, then you don't do it. I had to save for 4 years to pay for mine (I think it came out to around $5000 but I can't remember for sure anymore). The next most important thing is to follow every instruction and post-op care recommendation they give you to the letter. I wore those sleep goggles, stayed out of the pool, and avoided touching my eyes for 2x longer than they recommended.

Granted, my research on this is all 18 years old but this was not a brand new procedure even back then. I was convinced that the vast majority of horror stories came from people who did not go to good clinics or did not follow post-op care instructions. If you remove them from the dataset the procedure looks a whole lot less risky than what the naysayers in this thread would have you believe.