Hmm, interesting! I'd be worried that a little rotation will lodge a piece in the Kensington hole. How well does this design hold up to torque?

3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: or [email protected]

There are CAD communities available at: [email protected] or [email protected]

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe/ may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

Unfortunely, I can't real-world test since I don't have a printer. But FEM tells me that this device does well aganst torque (Aluminum). Pulling/Yanking is good too.

Give it a try, Axiochus! ;) A test plate is provided.

The issue I see is that you’ll have to prop up most computers to make it stay as they’re usually thinner than your lock.

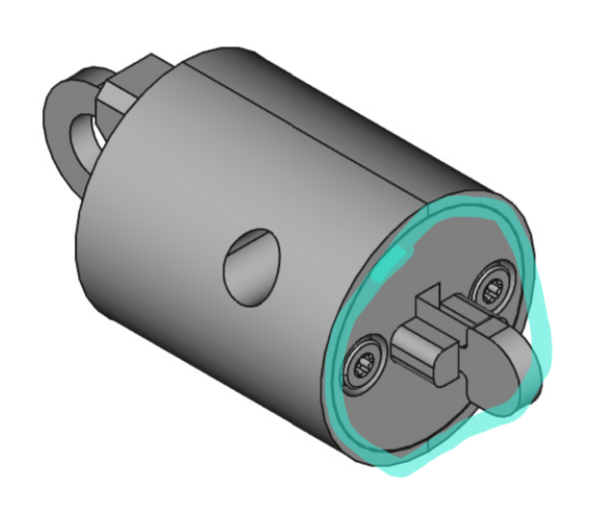

A tiny nudge will be applied since the ring guard passes the computer's casing. Thicker computers won't have this issue.

Some propping may be needed since the lock is quite large.

I dont get for what this is? To put a padlock on it? For what device?

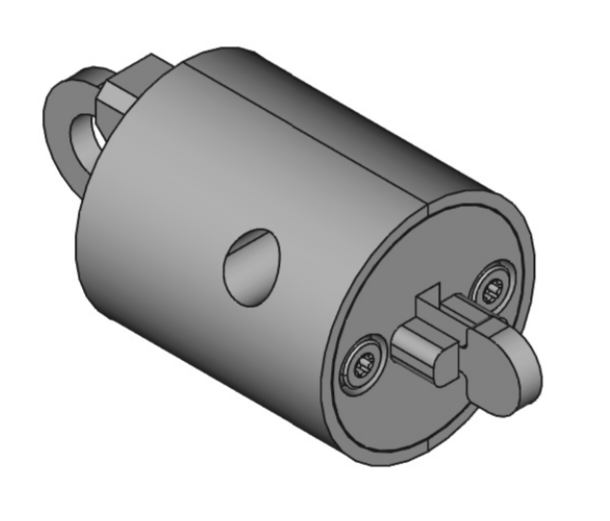

This is a lock to anchor your device to something.

If you have a laptop/desktop. Look to the side and you will see a Rectangle

This lock uses that hole and this will anchor the device. (Just need a cable.)

The offical K-Lock used by kensington are these.

Get it?

Thanks for the explanation. So these Kensington locks are super expensive? How does your desgin improve upon it?

Firstly, these are open-source for community improvement.

bending/tampering resistance by the use of guards.

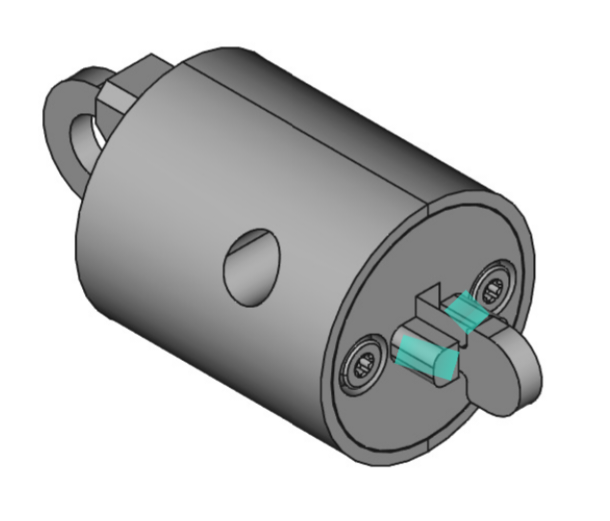

Front guard disallows the shackle from being bent.

The Back guard protects the back shackle from bending.

The ring guard protects tampering of the guards.

(This info below may be inaccurate since I changed partial lock design. FEM testing wasn't used right now.)

The shackle is designed to withstand 2-7k netwons. (2k when aluminum is used, 7k if steel is used.)

(This was found on the web. This may be mild/severly innacurate. Take this with a grain of salt.)

~200 Newtons are required to move a car.

Also the shackle tip is round instead of square. This improves the shackle from V-bending:

Kensington Shakle tip: ====[]

My shakle tip: ====D

(Don't throw out of context... :|)

And finally, it's cheap and easy to make.

And this is... plastic instead of metal? Or am I misunderstanding things?

The entire device should be 3d metal printed.

If you want a lighter device. Plastic works on:

- Body.

- Pin.

Metal is needed on:

- Front/Back guard.

- Shackle.

Oh, wow. I'm obviously new to 3D printing, but you can basically replace a forged piece of steel/brass!? If so, that's awesome!

Yes.

With PLA, you can submerge your part with sand and use molten metal. (PLA Casting)

3D printer can also print metals. You just need a special nozzle and metal fillament.