3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: [email protected] or [email protected]

There are CAD communities available at: [email protected] or [email protected]

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

Thanks for the explanation. So these Kensington locks are super expensive? How does your desgin improve upon it?

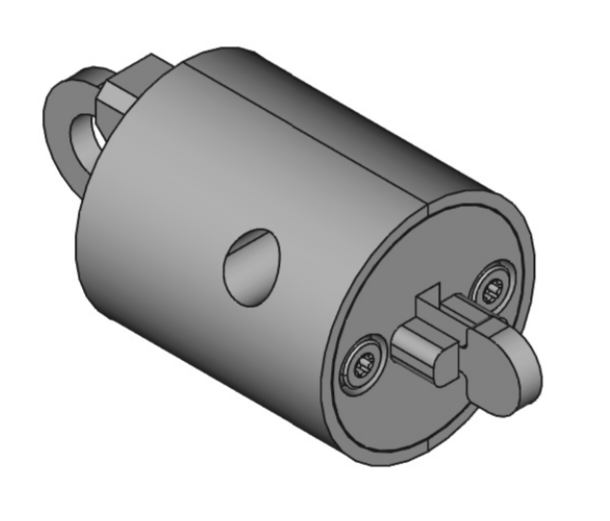

Firstly, these are open-source for community improvement.

bending/tampering resistance by the use of guards.

Front guard disallows the shackle from being bent.

The Back guard protects the back shackle from bending.

The ring guard protects tampering of the guards.

(This info below may be inaccurate since I changed partial lock design. FEM testing wasn't used right now.)

(This was found on the web. This may be mild/severly innacurate. Take this with a grain of salt.)

Also the shackle tip is round instead of square. This improves the shackle from V-bending:

Kensington Shakle tip: ====[]

My shakle tip: ====D

(Don't throw out of context... :|)

And finally, it's cheap and easy to make.

And this is... plastic instead of metal? Or am I misunderstanding things?

The entire device should be 3d metal printed.

If you want a lighter device. Plastic works on:

Metal is needed on:

Oh, wow. I'm obviously new to 3D printing, but you can basically replace a forged piece of steel/brass!? If so, that's awesome!

Yes.

With PLA, you can submerge your part with sand and use molten metal. (PLA Casting)

3D printer can also print metals. You just need a special nozzle and metal fillament.