3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: or [email protected]

There are CAD communities available at: [email protected] or [email protected]

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

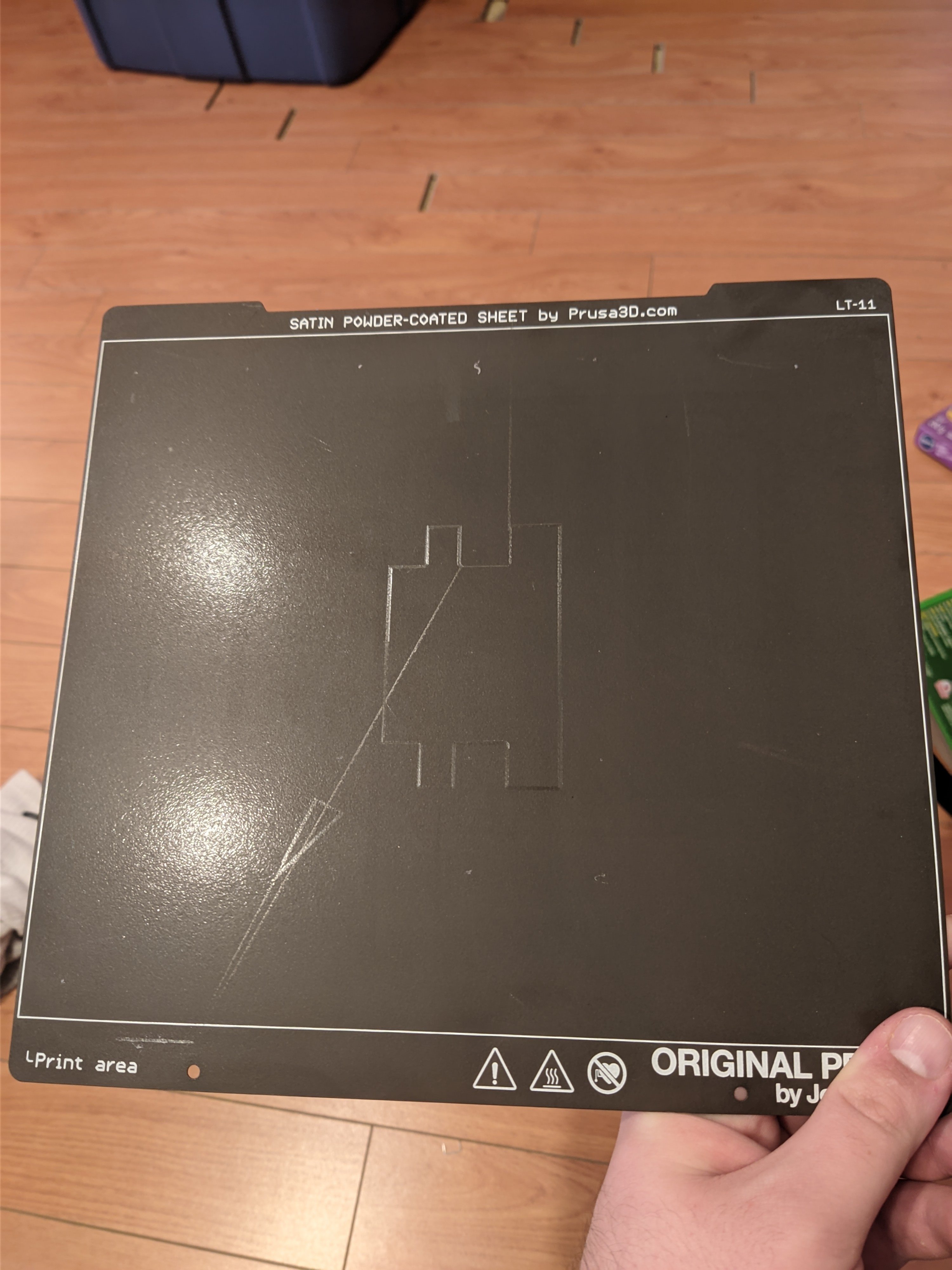

I just had to read up on the MK4 because I don't own one. Apparently this machine uses a load cell on the bed to detect the nozzle touch? That means that to home Z or mesh level the bed, the nozzle has to touch the build surface. This strikes me as a rather bad idea. I can think of tons of situations such as a pointy diamond or ruby nozzle, a very hot nozzle, or a nozzle with hardened crud stuck to it all causing damage to the print sheet, not to mention the potential for damage to the nozzle itself.

Ideally the nozzle should never, ever touch the print surface. For any reason.

There's a purpose behind things like the BL Touch having a soft plastic probe on the end.

In the cases you describe it should fail by ruining the print, not the build plate though. If there is something between the nozzle and the plate, it will be too far away from it after calibration, not too close.

Oh I've had my fair share of issues with this. i.e. little specs of the previous print color is stuck on the next print since I missed it during print clean up.

But if I am honest, for a normal spring steel PEI sheet it's perfect. And I prefer this to the magnetic solution like on the Mini since it lets me use Garolite/G10.

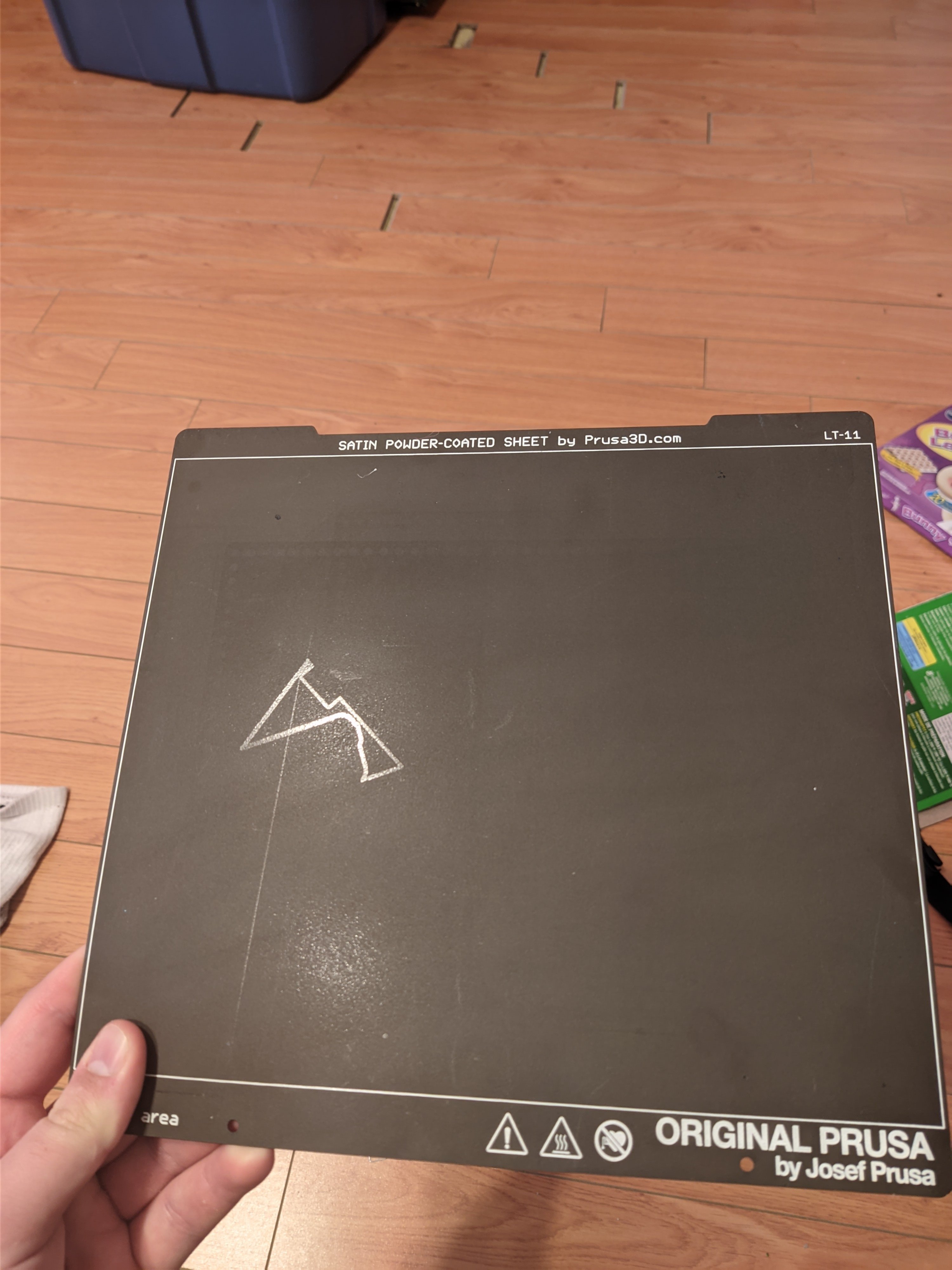

I've only seen this issue with the satin bed.

Hey, just wanna point out that having a touch sensor built into the nozzle is definitely not unheard of, my printer (Neptune 3 from elegoo) uses the same sensor. It's not the most reliable sensor in the world but it got the job done until I got my BLTouch.

They've stopped using the PINDA probe?

That was the best auto bed leveling system I'd seen because it stood half a chance of ever working. The biggest problem I would see out of them was, well...the whole carriage/extruder assembly was designed by a rock chewing moron.

I used to build and maintain the printers for a little company that 3D printed parts for their products back in the beforetimes, so I've had my fair share of Prusas apart. I don't think I could design a worse mechanism if I tried.

The extruder mechanism was a demented sandwich of parts that don't make sense all made in shiny black plastic so it's hard to see their shapes. You don't build it up from one side to another, you build it up from the inside out. All the wires are supposed to route through a hole in the back of the carriage, then get pinched between the carriage and the extruder body in a couple channels that bend them at sharp right angles. The whole extruder mechanism is a demented sandwich built up from the inside out that doesn't let you easily remove and replace any of the working parts. ANY service to the extruder group, be it a new nozzle, a new fan, a new thermistor, is a complete teardown and rebuild, partially because there are no electrical connectors at that end, all the wires are 16 inches long and run all the way back to the main board. And the PINDA probe mount wasn't a separate bracket that bolts on, it's a feature of the largest, most central piece of plastic and it's attached by a thin little shard of plastic that WILL soften and deform in service.

In the case of a heavily used printer, say for production or a busy prototyping lab, you can't just have a spare extruder built up ready to bolt on and go. You can't have a hot end built up on the bench ready to swap in. If one needs maintenance or repair, it will take hours, no matter how minor the job.

It was like working on a Macbook built by BMW. I didn't charge enough for my time.

If you're bed leveling with a heated nozzle, you're not doing it right.

Shouldn't you make your adjustments while the bed and nozzle are at least partially heated, since metal expands when heated? If you adjust z-offset when cold, the nozzle may expand a bit, decreasing the gap. At least that's my understanding, and why most printers I've seen will preheat the bed and nozzle before doing bed leveling

If you’re using something like a tap or anything that uses the nozzle as the probe then you do want the bed and nozzle to be at temp (or close) so any thermal expansion is included.

Same applies if you’re using something like auto Z offset (since it’s going to be hit with the probe AND nozzle)

If you’re using something like a Klicky or BL touch then you need the bed to be temp but the nozzle doesn’t matter since you’re measuring with the probe. But… you do want the nozzle to be at temp when calibrating the Z offset so the right figure is used.

Personally… I have a Klicky (Klackender actually) and heat the bed and then dial in the zoffset with a print and baby stepping

Sure, but that doesn't mean there won't ever be some situation where it'll try to Z home for whatever reason, or even if it's just user forgetfulness, and you poke the PEI sheet with a 215+ degree nozzle. The fact that the mechanism inherently includes that possibility is stupid.

The printer won't do any leveling with a fully heated nozzle.

The MK4's we use at work and my personal MK4 all heat up to 170 before bed leveling, and if you previously swapped filaments before leveling, the printer will pause and wait until the nozzle has cooled down to the target range before initiating bed leveling.

Well, then at least they thought of that. Will it Z home with the nozzle preheated? I'll bet you it will.