3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: or [email protected]

There are CAD communities available at: [email protected] or [email protected]

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

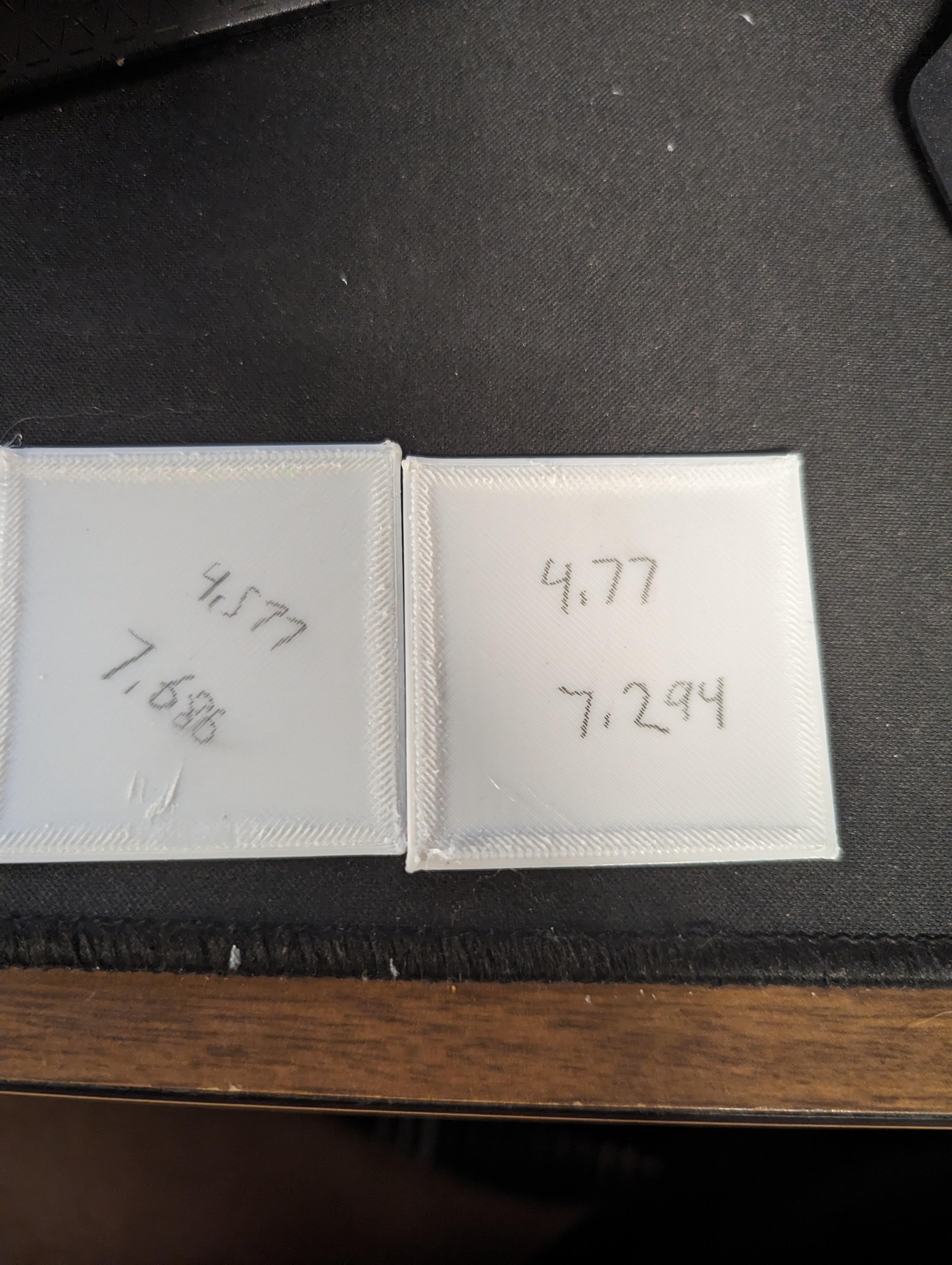

Seems like it's squishing when the printhead decelerates and accelerates again around the corner. Perhaps the temperature is too high so too much material oozes out when speed is decreases?

I agree, not just the perimeter but also when it's going back and forth to fill in the centre area. I'm not sure how to address it -- maybe the pressure advance settings LazaroFilm suggested. I've also tried printing at a series of different temperatures..

That's what I meant, have you tried just decreasing the printing temp by 10 degrees and then printing another square and comparing the result?

Yes. For this petg I've tried nozzle temps ranging from 210-240.

Have you tried swapping out the nozzle? Maybe it's worn down