3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: [email protected] or [email protected]

There are CAD communities available at: [email protected] or [email protected]

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

This is the answer with anything based on slic3r in my experience.

Is this your model @op? If yes, you can add two rectangles to either side of the hole that are 0.25mm or so in height to serve as a built in bridge and trick the slicer.

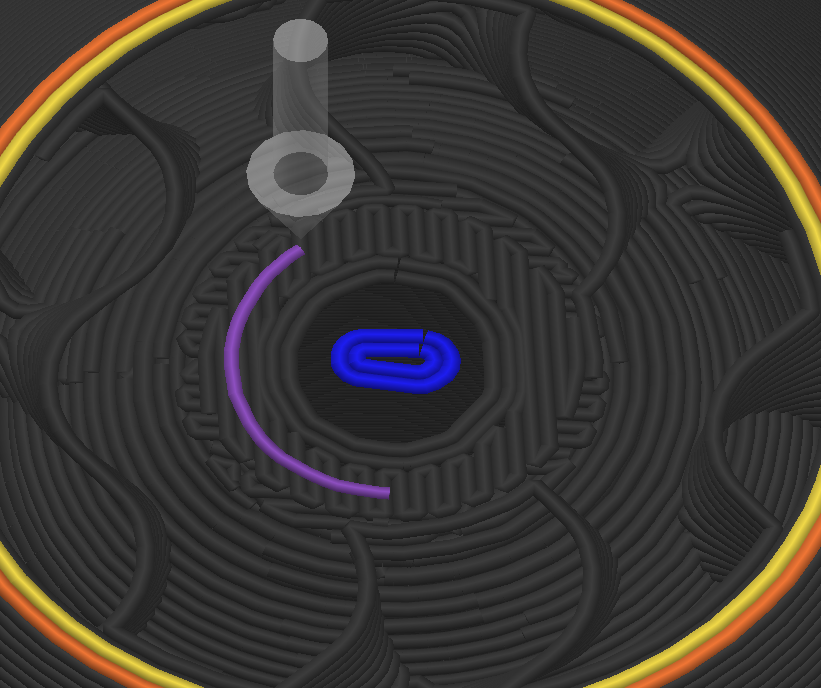

Not my model (Added source to my post). That was a good idea, though. What I ended up doing (and can't believe I didn't think of it sooner. Been a long day...) is adding a 0.2mm disk right at the problem height and it's looking good!

I got the idea while building my Voron - the designers bake a lot of tricks like this into their files. I've adopted a lot of them to improve printability and am happy to share the knowledge!