And then vote for Ranked Choice Voting (which may not be the ideal but is a paradigm shift improvement from First Past the Post).

pageflight

Thanks, guess I got lucky!

Is there a self hosted OpenTelemetry consumer?

I think they can be a climate conscious choice and unaffordable. But getting better, and still a worthwhile step.

Unfortunately I don't have anywhere to burn them, but maybe I'll save some for camping trips.

Hah, thanks, I do think hand tools have a beauty to them.

Thanks! We compost and know folks with chickens, good suggestions.

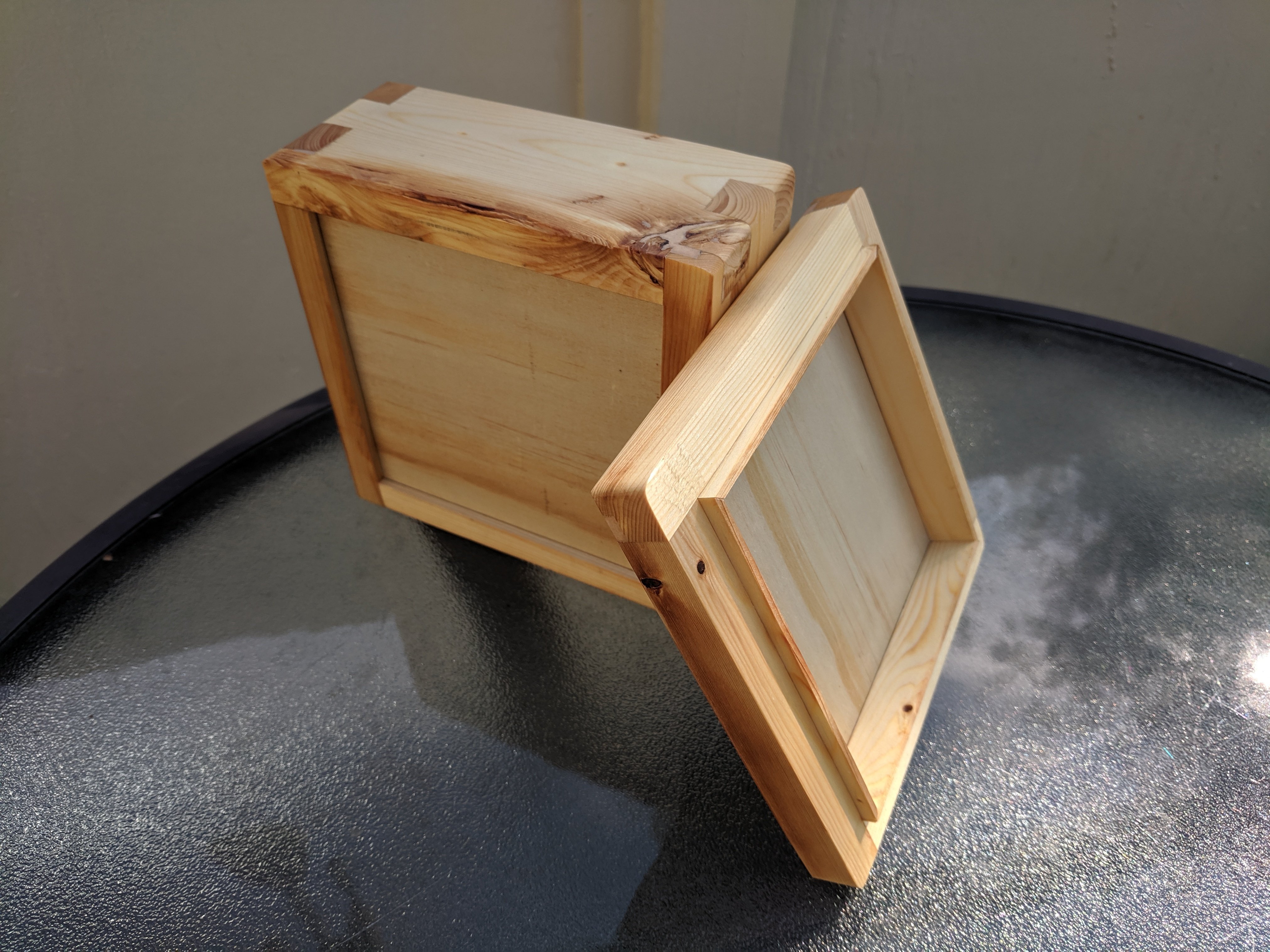

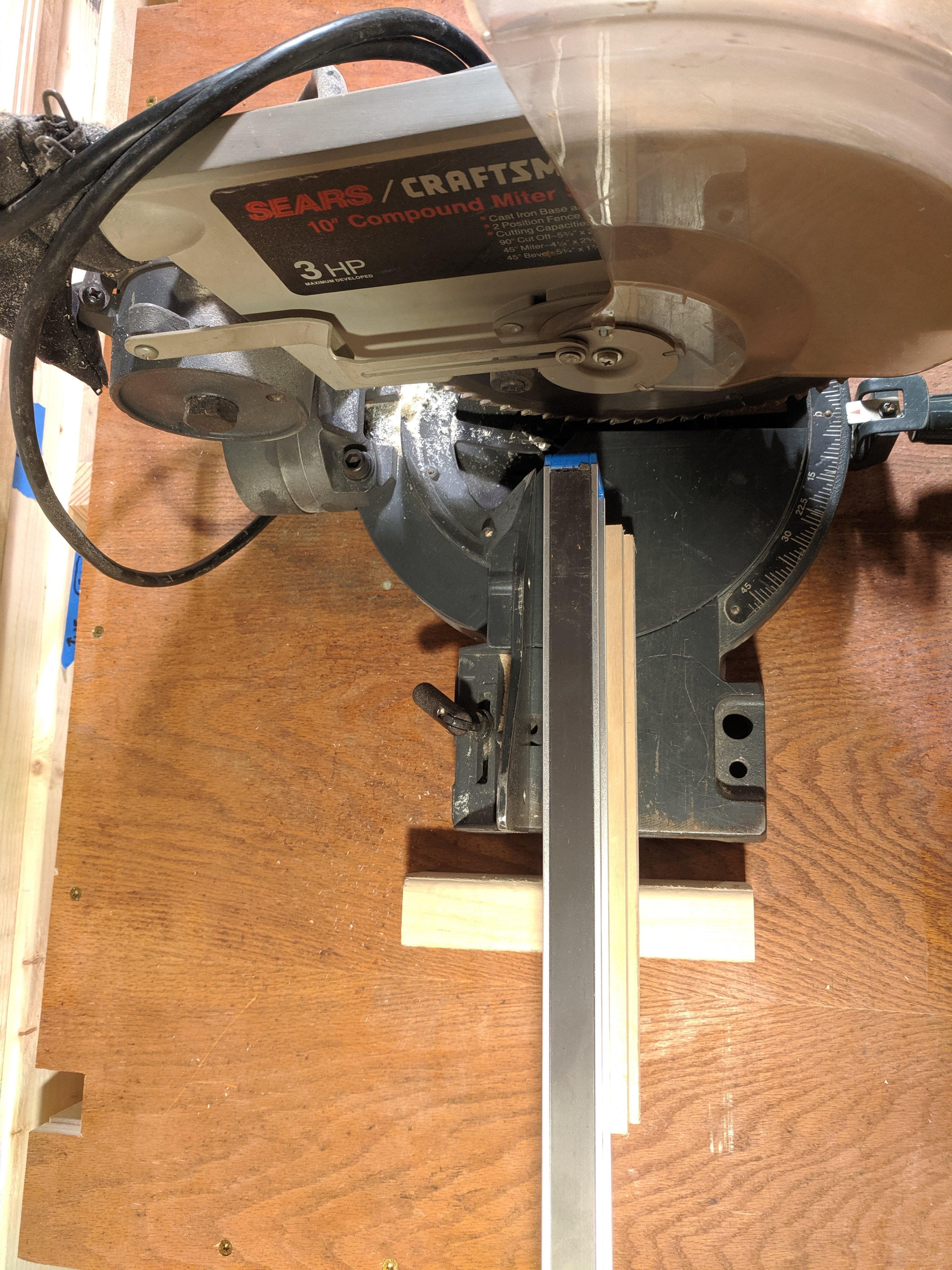

Took me a minute to figure out how it works. So the angle of the jig is determined by the length the chisel extends through it. Neat.

Always checking for buttons. From JD Power:

Looks like climate and possible media volume have physical controls, so pretty good.

Thanks! I want to try some smaller / varying size fingers next.

Good to know!

This is mostly for entertainment, not harvest yield.

Is there some kind of aurora alert I can sign up for? Missed the last one, barely caught some of this one.