Mildly Infuriating

Home to all things "Mildly Infuriating" Not infuriating, not enraging. Mildly Infuriating. All posts should reflect that.

I want my day mildly ruined, not completely ruined. Please remember to refrain from reposting old content. If you post a post from reddit it is good practice to include a link and credit the OP. I'm not about stealing content!

It's just good to get something in this website for casual viewing whilst refreshing original content is added overtime.

Rules:

1. Be Respectful

Refrain from using harmful language pertaining to a protected characteristic: e.g. race, gender, sexuality, disability or religion.

Refrain from being argumentative when responding or commenting to posts/replies. Personal attacks are not welcome here.

...

2. No Illegal Content

Content that violates the law. Any post/comment found to be in breach of common law will be removed and given to the authorities if required.

That means: -No promoting violence/threats against any individuals

-No CSA content or Revenge Porn

-No sharing private/personal information (Doxxing)

...

3. No Spam

Posting the same post, no matter the intent is against the rules.

-If you have posted content, please refrain from re-posting said content within this community.

-Do not spam posts with intent to harass, annoy, bully, advertise, scam or harm this community.

-No posting Scams/Advertisements/Phishing Links/IP Grabbers

-No Bots, Bots will be banned from the community.

...

4. No Porn/Explicit

Content

-Do not post explicit content. Lemmy.World is not the instance for NSFW content.

-Do not post Gore or Shock Content.

...

5. No Enciting Harassment,

Brigading, Doxxing or Witch Hunts

-Do not Brigade other Communities

-No calls to action against other communities/users within Lemmy or outside of Lemmy.

-No Witch Hunts against users/communities.

-No content that harasses members within or outside of the community.

...

6. NSFW should be behind NSFW tags.

-Content that is NSFW should be behind NSFW tags.

-Content that might be distressing should be kept behind NSFW tags.

...

7. Content should match the theme of this community.

-Content should be Mildly infuriating.

-The Community !actuallyinfuriating has been born so that's where you should post the big stuff.

...

8. Reposting of Reddit content is permitted, try to credit the OC.

-Please consider crediting the OC when reposting content. A name of the user or a link to the original post is sufficient.

...

...

Also check out:

Partnered Communities:

Reach out to LillianVS for inclusion on the sidebar.

All communities included on the sidebar are to be made in compliance with the instance rules.

view the rest of the comments

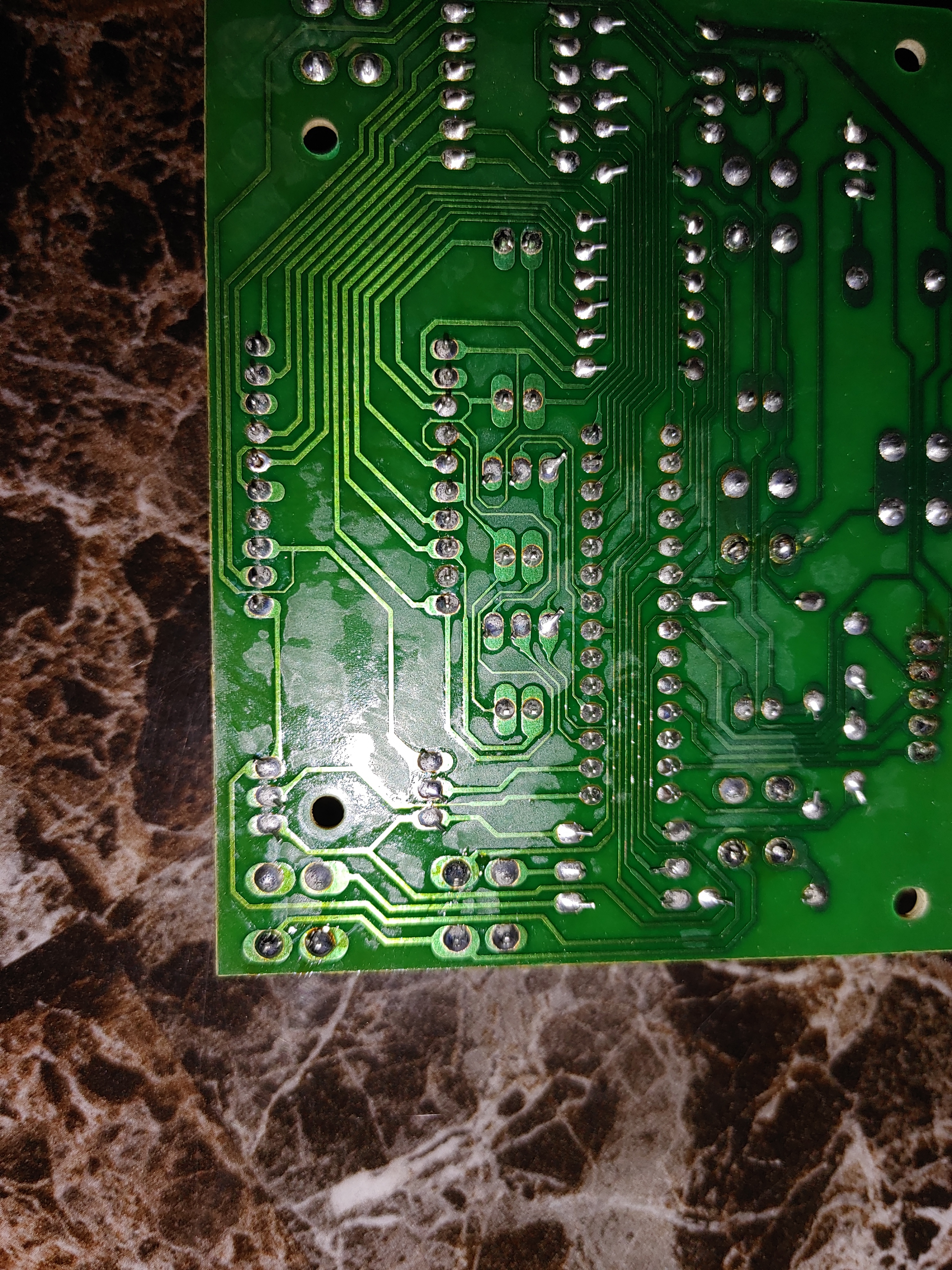

Care to elaborate, for those not as experienced as soldering? This isn't the most relatable post without some additional context.

For instance, my only experience soldering is with audio equipment (think wires and potentiometers), never with PCBs and I have no clue what you mean.

Solder is a low melting point metal used to join two metals, where the solder fills the gap and bonds to both metals. This is commonly used in electronics to bond components to the board. For a good solder joint, the solder must be brought up to the proper temperature, and the pads on the PCB (metal 1) and leads of the component (metal 2) need to be heated enough. Additionally, flux is added to the solder to remove oxides on the component leads and PCB pads to allow the solder to bond to the metal; oxides can prevent the solder from sticking.

A cold solder joint is one that does not reach the proper temperature and/or does not have enough flux, leading to the solder not bonding to the joint, having a scaly/bubbly/matte appearance, and a weaker more brittle joint. Flux also doesnt do as good a job at lower temperatures so it's important for the joint to get hot enough, and to heat the pads/component leads too

Then with my shitty ass soldering iron and skills I overheat the surrounding components while attempting to bring the soldering spot to temperature...

This is a circuit board from my slow cooker. It quit heating a week ago so I opened it up and found a broken wire. That was easily fixed.

I figured while I had it apart I should look at the display board and see if I can fix the missing segments. I resoldered the one pin but nothing changed.

Unfortunately my eyes arent what they used to be so the others someone pointed out will be a challenge.

5th pin down on the far left side in the picture.

There's no solder on the pin.

Most of the joints are questionable, that one is flat out bad.

Get some cheap magnifying glasses with a light.

Oh, that makes more sense. The heat from the malfunctioning cooker may have resoldered these points badly.

I was curious how like half the points were bad, and that could explain it.

e: especially since they’re all at the bottom half of the board. That was closest to the heating element, right?

That'd be about right. There's insulation inbetween.

Unlikely any heat from the slow cooker did anything. Solder melts at 370F. A slow cooker is never going to get anywhere close to that hot.

Strange that all the bad points are in the lower half of the board, and that most points in that half are bad, then.

e: could a malfunction make it heat beyond 370f?

It's most likely that it's related to the original manufacturing. These will be machine wave-soldered, not hand soldered, and having quality vary across the board isn't impossible if the setup/operators were less than ideal.

Perhaps. It still seems odd to me that this board was mounted vertically inline with the heating element and the bad parts I identified line up with that, before I knew that was the case:

Cold solder is what happens when the solder didn't quite reach the temperature needed to completely melt and do contact, so it looks brittle and would be potentially a faulty connection.

With that said I couldn't spot it in the pic

There are a bunch of questionable solder joints.

Like half the pins.

But the absolute worst is the 5th pin down on the far left side. There's so little solder used that you can see into the hole.

A few others are also a bit lacking as well. Almost all of the joints are ugly as sin...

!remindme 24h