this post was submitted on 28 Mar 2024

43 points (97.8% liked)

Machinist

718 readers

1 users here now

From Newcomers to Old Timers, a community united by the Industry of Machining

Rules Don't post illegal stuff

Don't post Porn (no sexy aluminum surface finishes don't count)

Don't be an asshat (harassment, bullying etc.)

If you're going to post NSFW stuff, flag it as NSFW, It's ok to post shop Screwups (blood/cuts) just make sure to flag it as NSFW

and Finally make sure to have a good time :D

founded 2 years ago

MODERATORS

you are viewing a single comment's thread

view the rest of the comments

view the rest of the comments

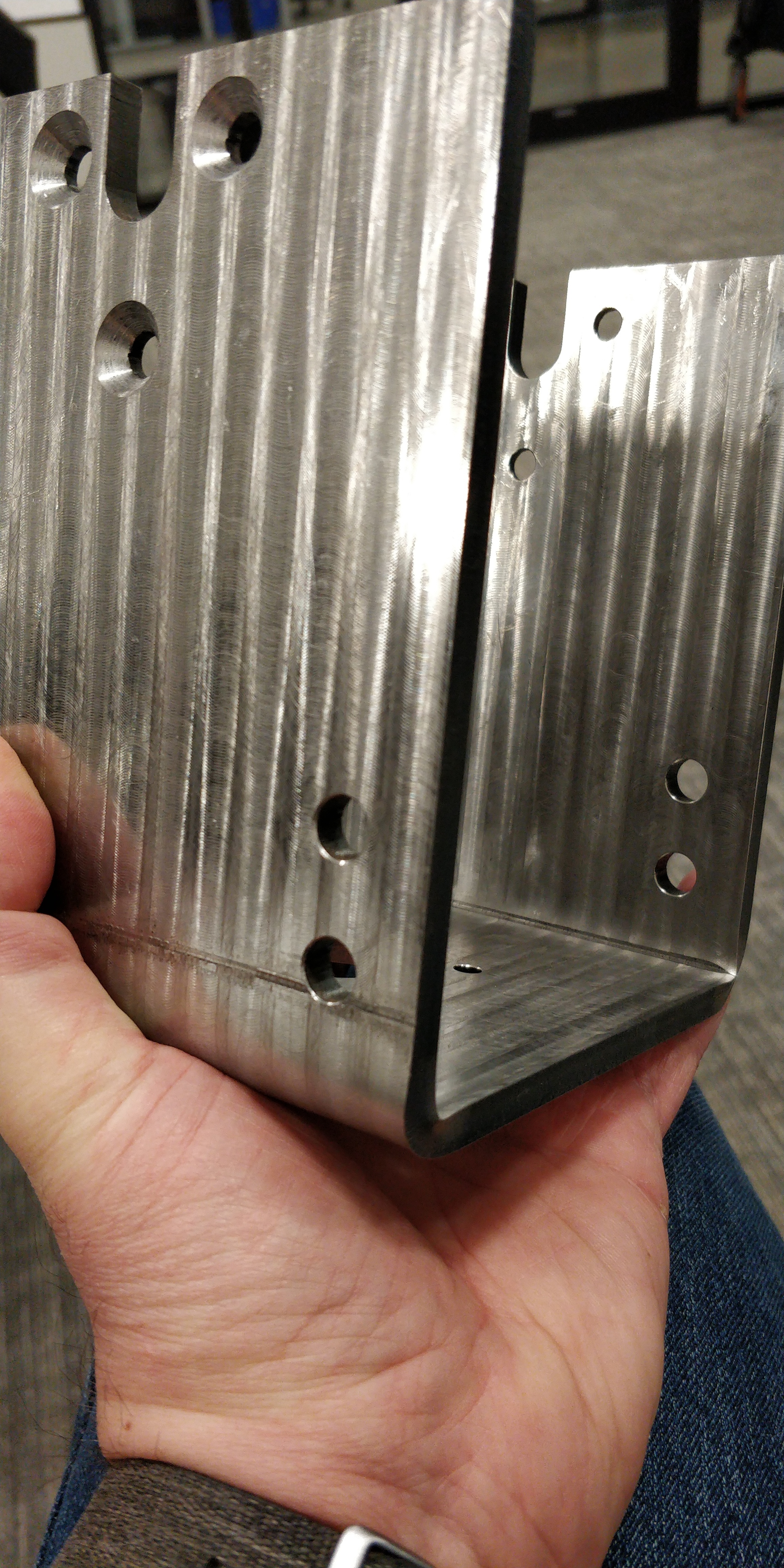

I'd guess they started with 8mm plate and faced it to get to your 1/4" spec and ensure they meet your specified tolerance.

Probably cheaper than finding accurate 1/4"plate in China.

Probably, but why'd they do it with a tiny little end mill?? You'd think Blanchard grinding or at least using a fly cutter would be way faster/cheaper.

No clue. Maybe they have a ton of one size endmill and that's all that's loaded.... Doesn't really make sense though, would be simple enough to swap the tools in setup.

Only thing that does make sense is they were doing another job with the same material and needed just that finish, or were out of slots in the changer, etc.