Machinist

786 readers

4 users here now

From Newcomers to Old Timers, a community united by the Industry of Machining

Rules Don't post illegal stuff

Don't post Porn (no sexy aluminum surface finishes don't count)

Don't be an asshat (harassment, bullying etc.)

If you're going to post NSFW stuff, flag it as NSFW, It's ok to post shop Screwups (blood/cuts) just make sure to flag it as NSFW

and Finally make sure to have a good time :D

founded 2 years ago

MODERATORS

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

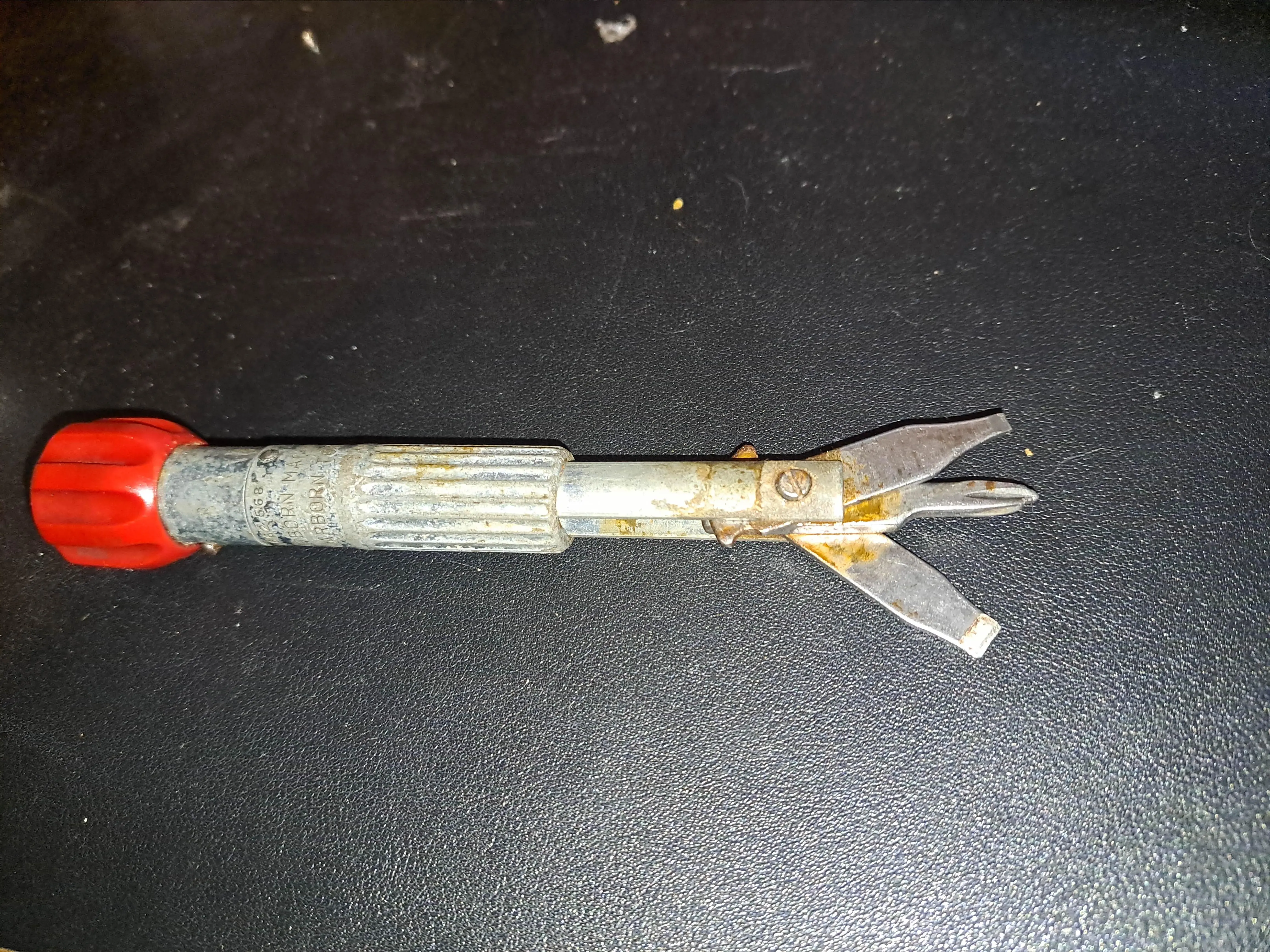

closed

closed opened

opened philps

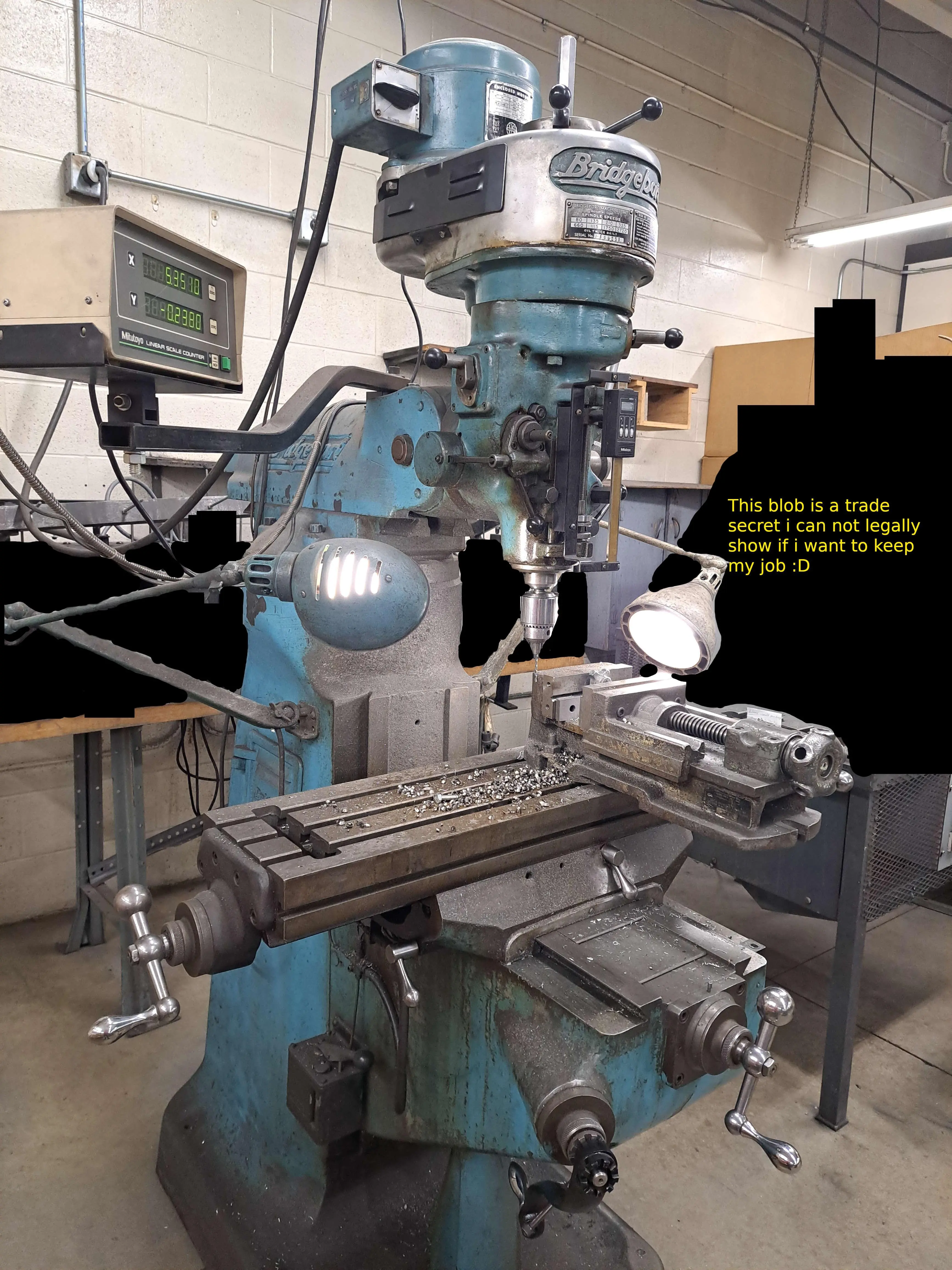

philps ratchet mechanism #

ratchet mechanism #

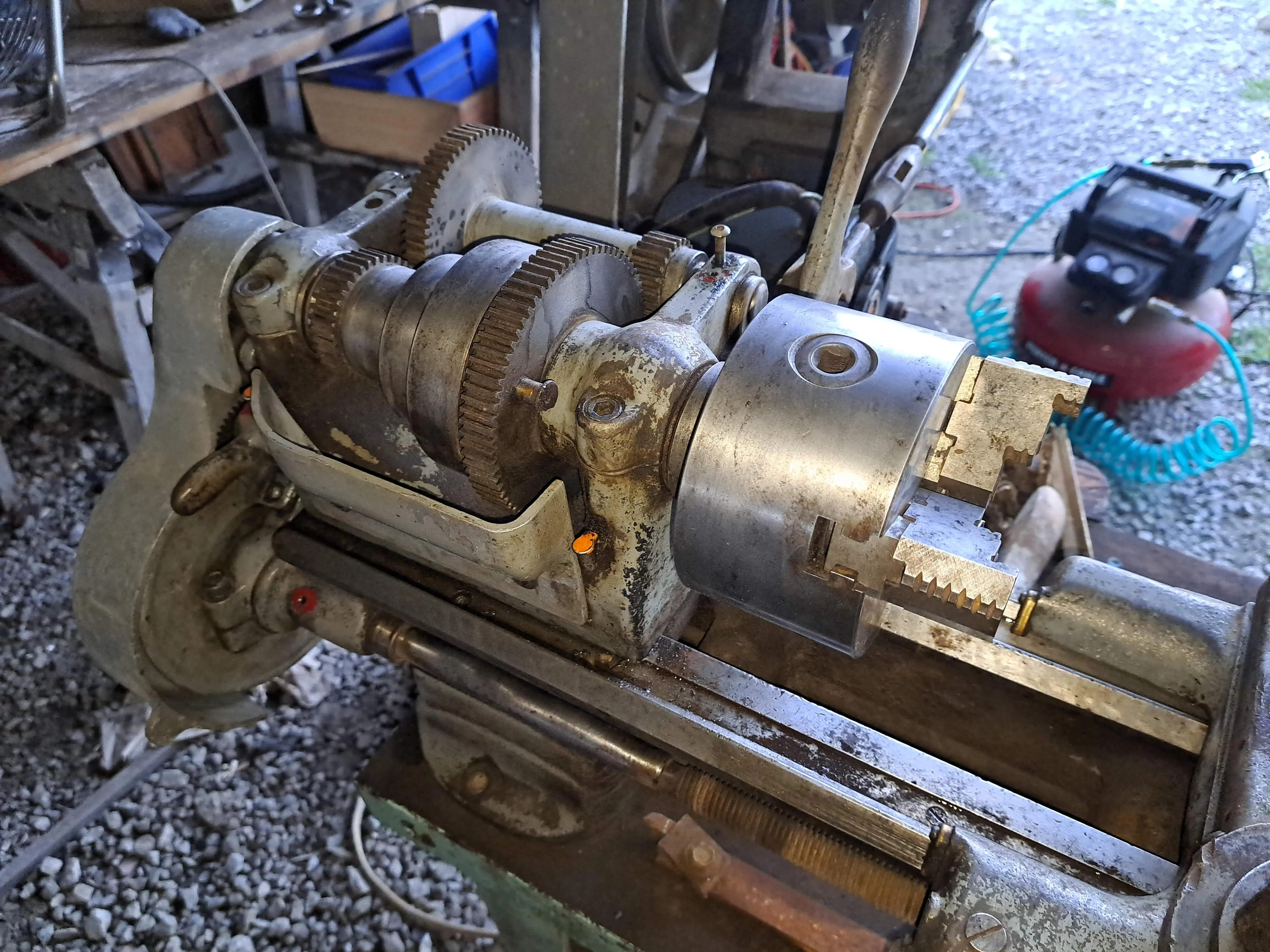

the gears are MINT!!!

the gears are MINT!!!

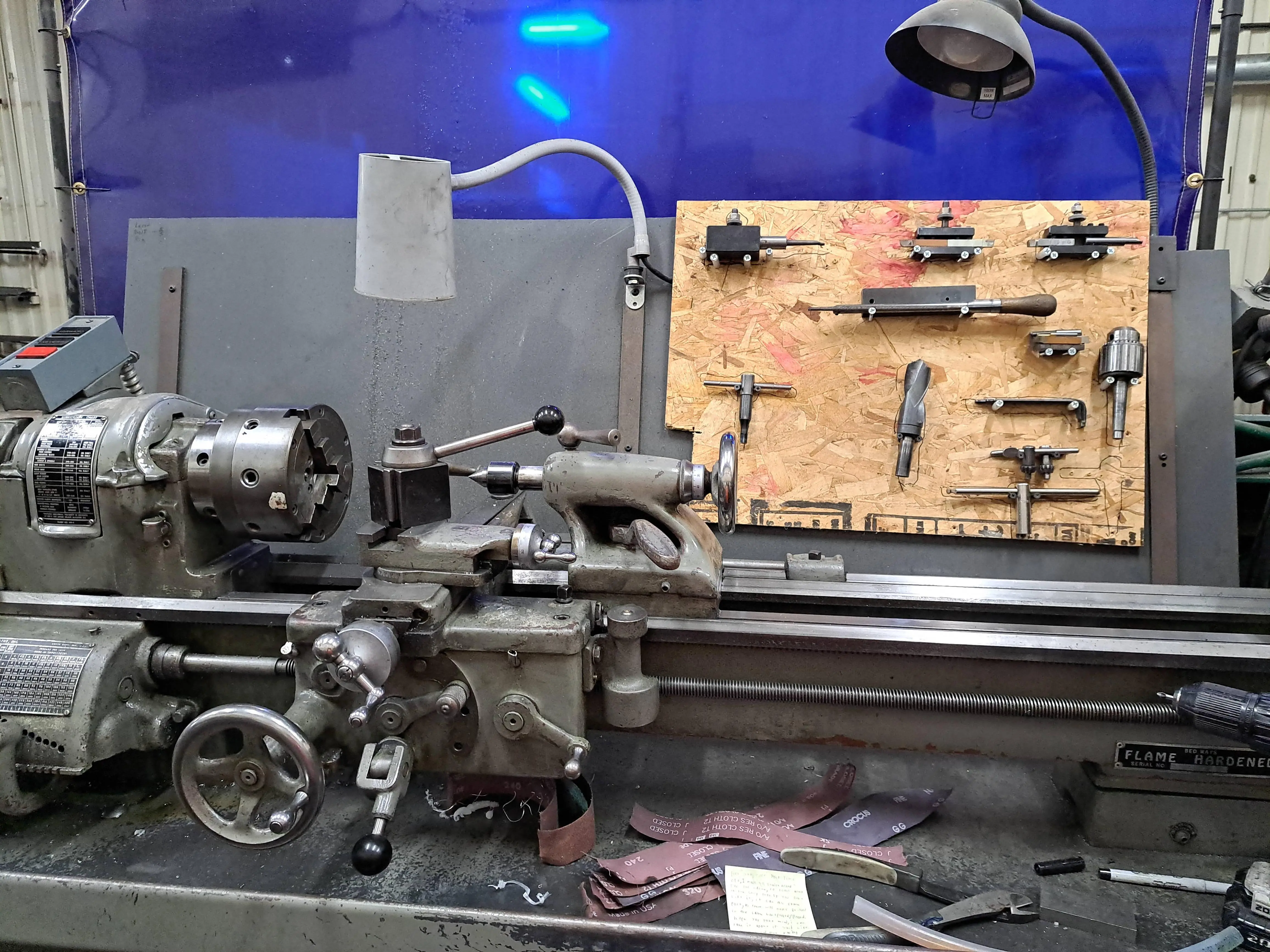

before

before after

after this was patented in 1912 so its pretty damn old

this was patented in 1912 so its pretty damn old