dnl

looks great! what did you use to design the case and and how did you make this rough surface finish? It looks very good on the outside and will be good at hiding scraches!

Haven't tried regular-sized choc switches before, but they should work. One thing to consider would be that with the heigher switches, the scroll wheel might be harder to reach with the thumb because it might be physically hidden behind enter/space. Should not be a problem if you are used to use the index for the wheels though.

I use my thumbs for the scrollwheels. My previous build was a sofle but the knobs always bothered me. They stick out too much, make it hard to transport the keyboard and I got into a habit of turning them with my thumb+index, so leaving the home row. With the wheels, using them feels much more natural!

there is another one that does something similar but that is not open source as far as I can tell: https://github.com/sprengboard/choccy

yeah they are a bit expensive. But they are worth it imho. Scrolling with the thumb on them feels very natural and the height is very similar to the chocs!

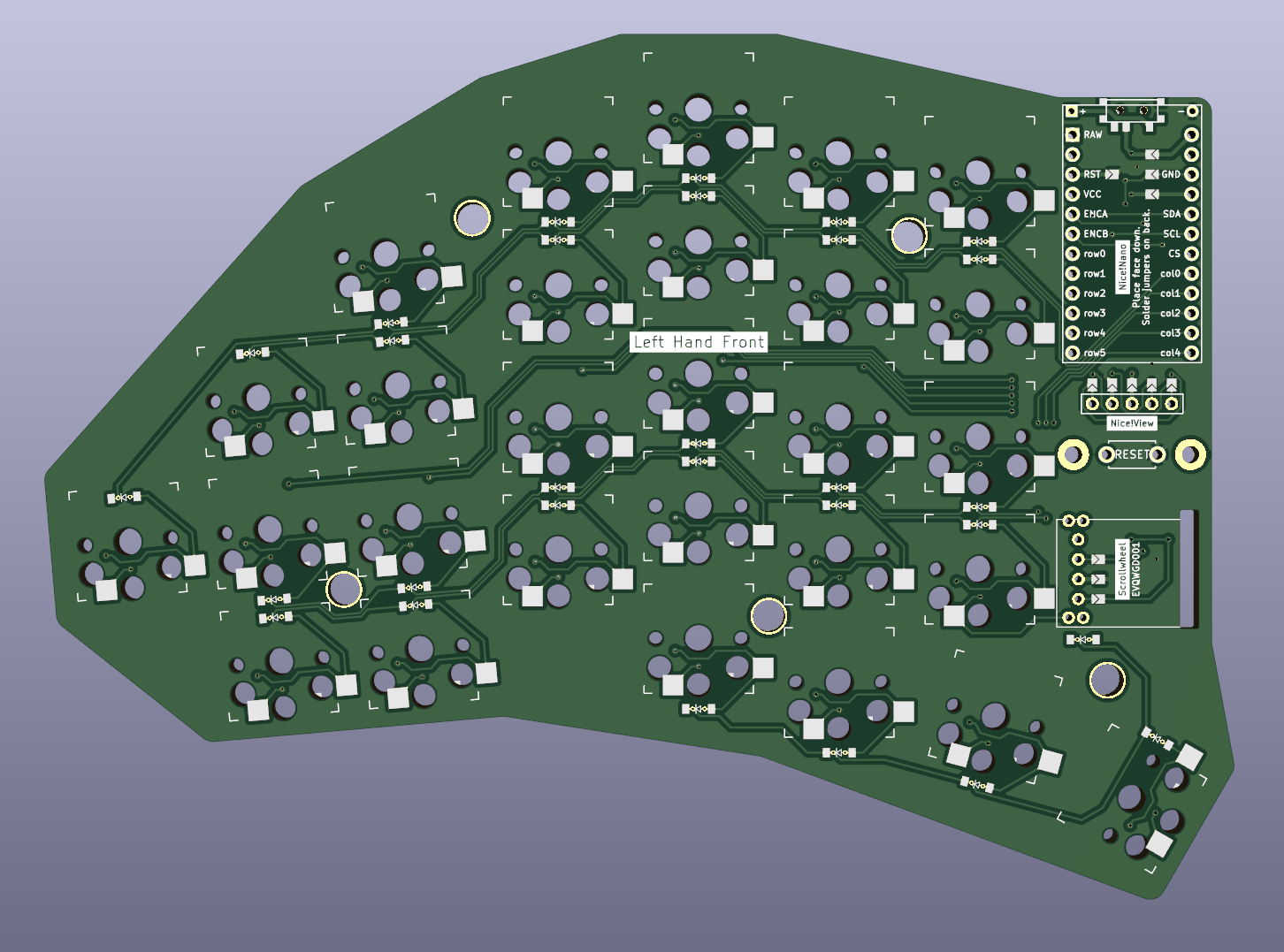

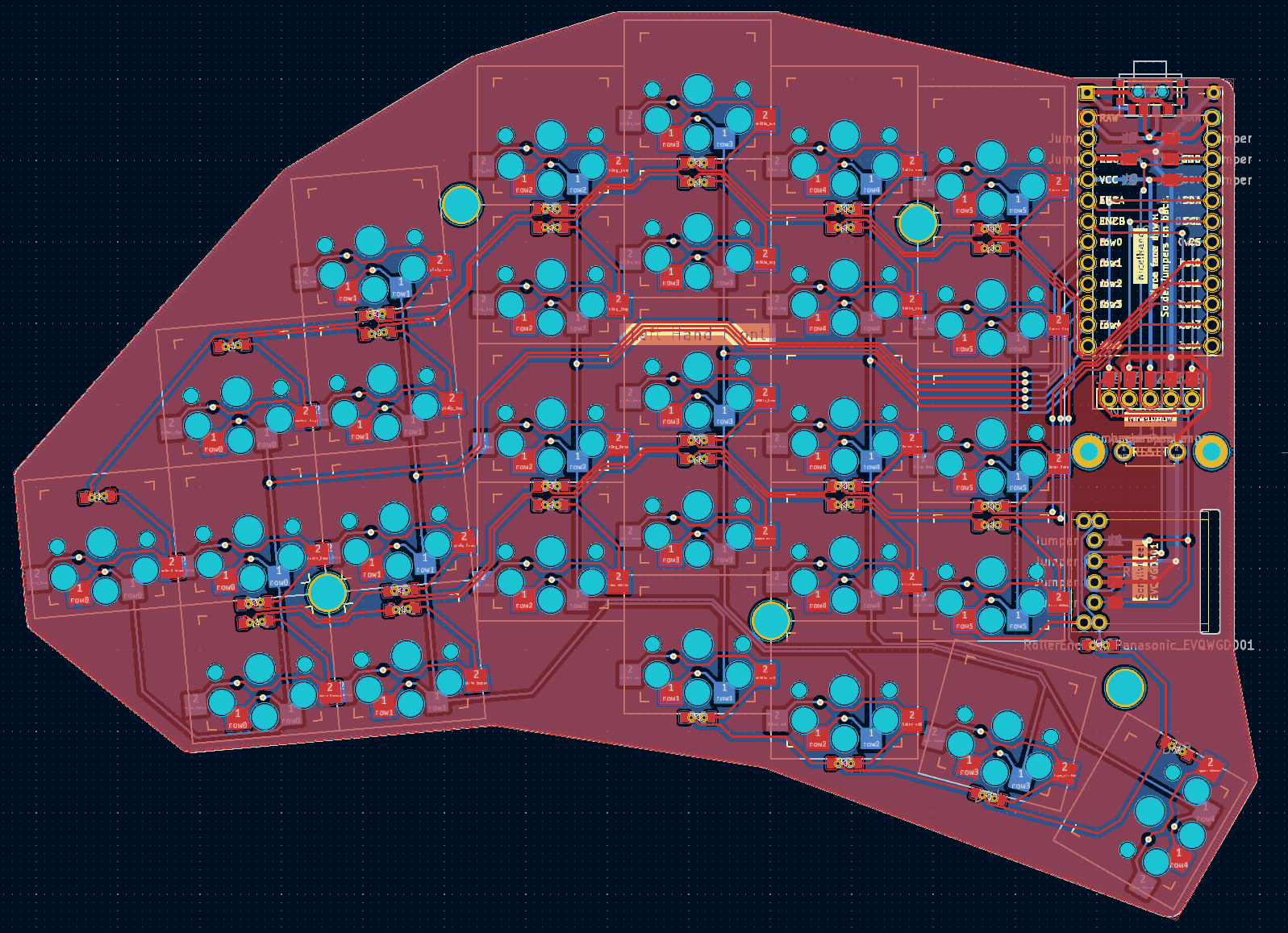

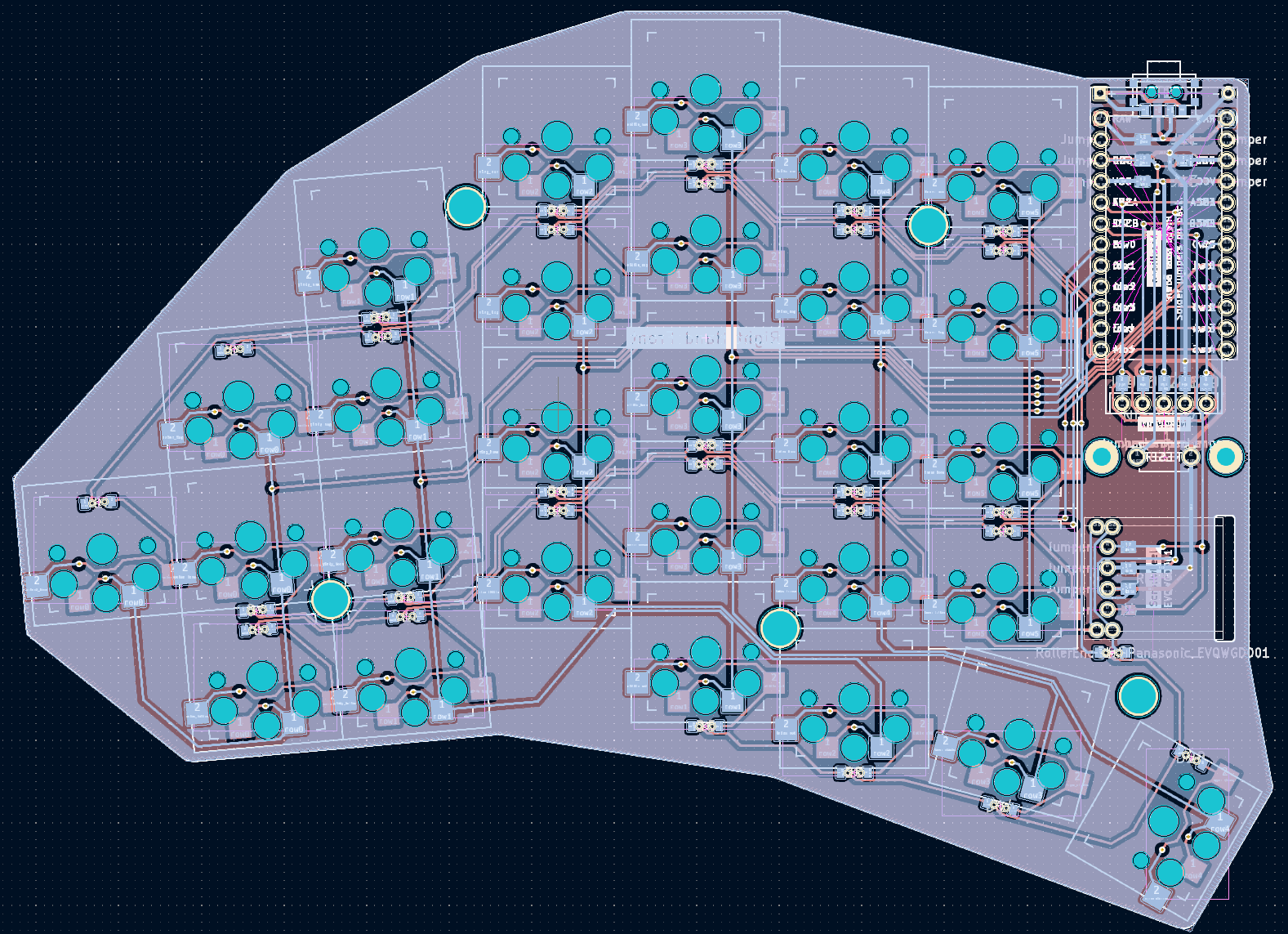

I just kept the default value (I think its 0.2mm) between traces. I could probably double it at some points where multiple traces are bundled though. Thanks for the hint!

thanks for the imput. Do you mean I should just place some random vias to connect both sides of the ground plane? To be honest, I dont understand exactly what this ground plane is used for since none of the traces actually connect to it. Is it merely for shielding against signal noise?

Hey, unfortunately erdogen, which I used to generate the starting point for the pcb does not generate a schematic file. It only generates the PCB and ratsnest for the footprints. So I dont have one. I think I could create one though. Mind telling me what this is used for and why one should have one?

No, you solder it in the same way for both sides.

The "flipping" is handled mostly internally. For The right hand side, the firmware just maps the rows and columns differently than for the left hand side. For pins where this is not possible (Vcc, Gnd,..), there are jumpers on the other side that need to be soldered.