3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: [email protected] or [email protected]

There are CAD communities available at: [email protected] or [email protected]

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

Why would that be? There is no physical rule saying that narrow extrusions need to be flatter as well.

Because the same squeezing effect shown in the 2d plane would occur on the 3d plane as well.

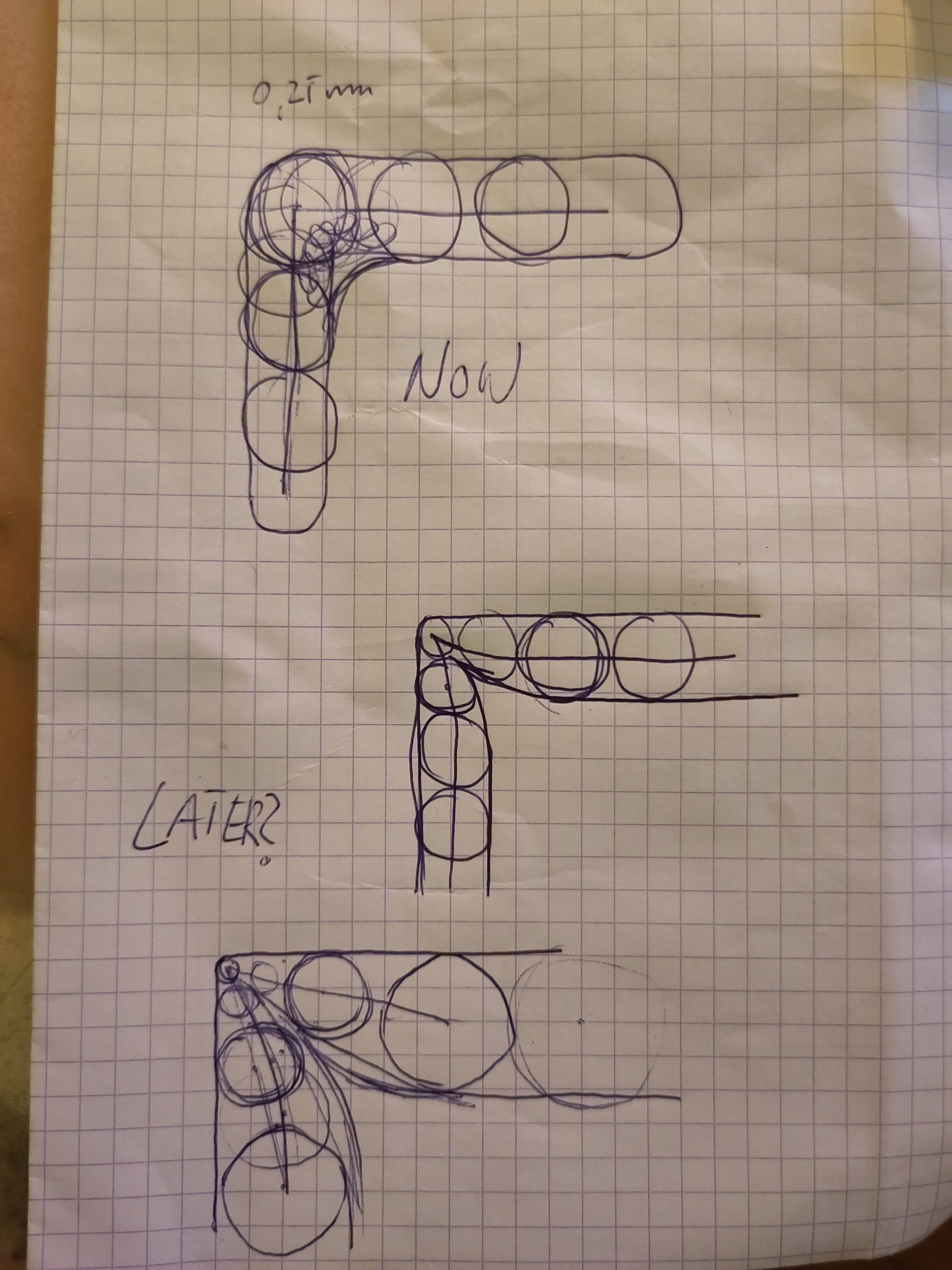

Hmm, not exactly sure I get your argument. I imagine every extrusion to tip slightly to the outside of the curve since material is elongated on the outside and squeezed on the inside. The excess material would be pushed to the inside while the outside of the curve would sink. Is that what you mean?

in 3d space, your corner extrusion would suddenly be much thinner, so the choices for your filament would be to either droop to be supported by the previous layer or for the filament to sit underextruded in space if your part cooler is really up to the challenge.

Why would it suddenly be much thinner?

Because that's what happens when you reduce the amount of material being extruded in order to create much thinner lines in order to create sharper corners.

But the corners will have the same amount of material, since it is basically extruding 2 times on the same location during a corner.

Which is why the original corners have too much material.

At this point there is basically only one way of knowing :D. I'll generate some g-code and give it a go.

It's all a question of what exactly "much thinner" means, I expect to have some positive effect of the proposed method even when the minimum extrusion width is above the threshold where things become too thin.

Overall I expect the described method to make more sense with large nozzles and wide extrusions.

Thanks for explaining what you mean!

Explained it above - https://lemmy.world/comment/6119616