Machinist

664 readers

108 users here now

From Newcomers to Old Timers, a community united by the Industry of Machining

Rules Don't post illegal stuff

Don't post Porn (no sexy aluminum surface finishes don't count)

Don't be an asshat (harassment, bullying etc.)

If you're going to post NSFW stuff, flag it as NSFW, It's ok to post shop Screwups (blood/cuts) just make sure to flag it as NSFW

and Finally make sure to have a good time :D

founded 1 year ago

MODERATORS

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

14

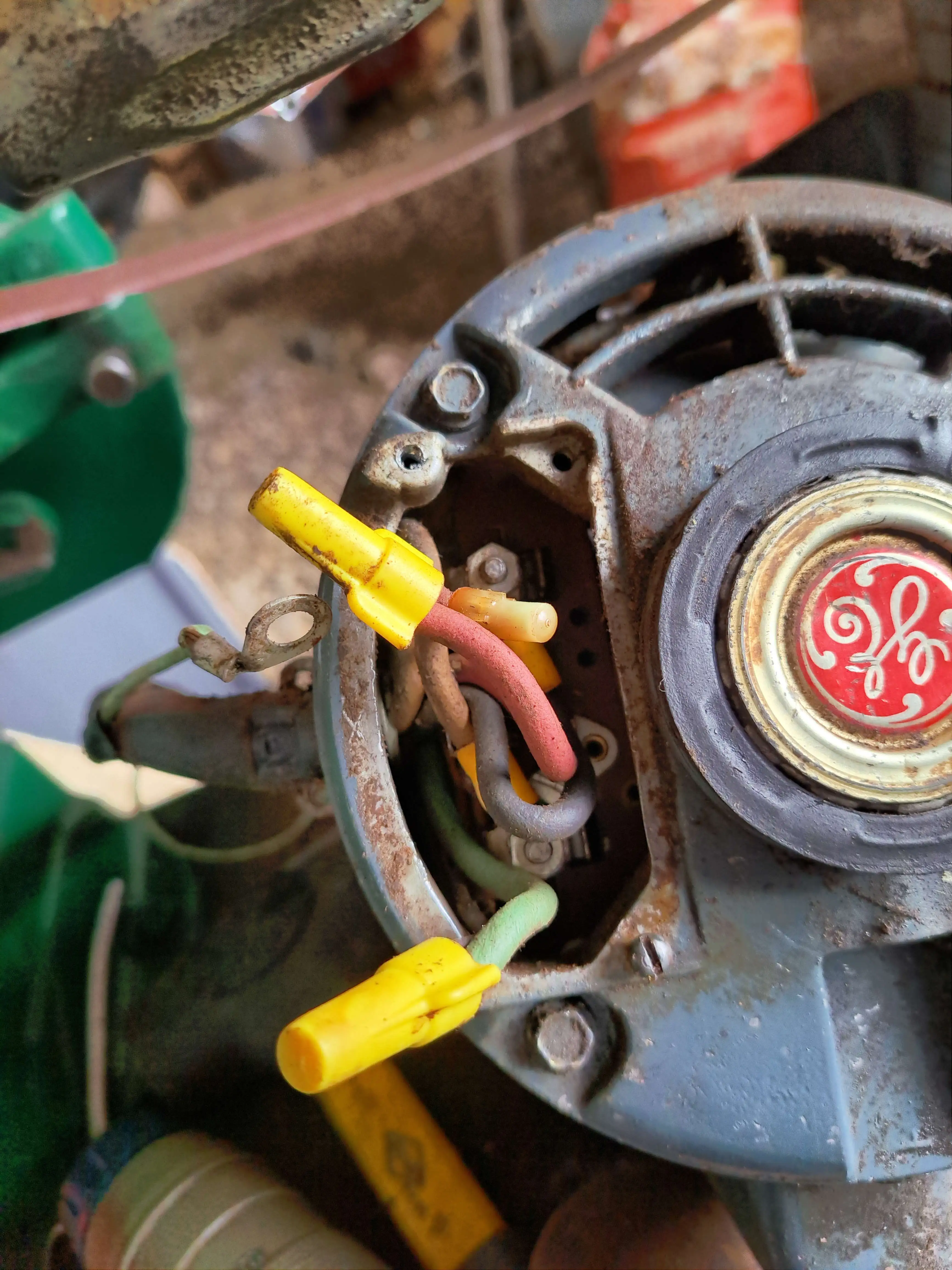

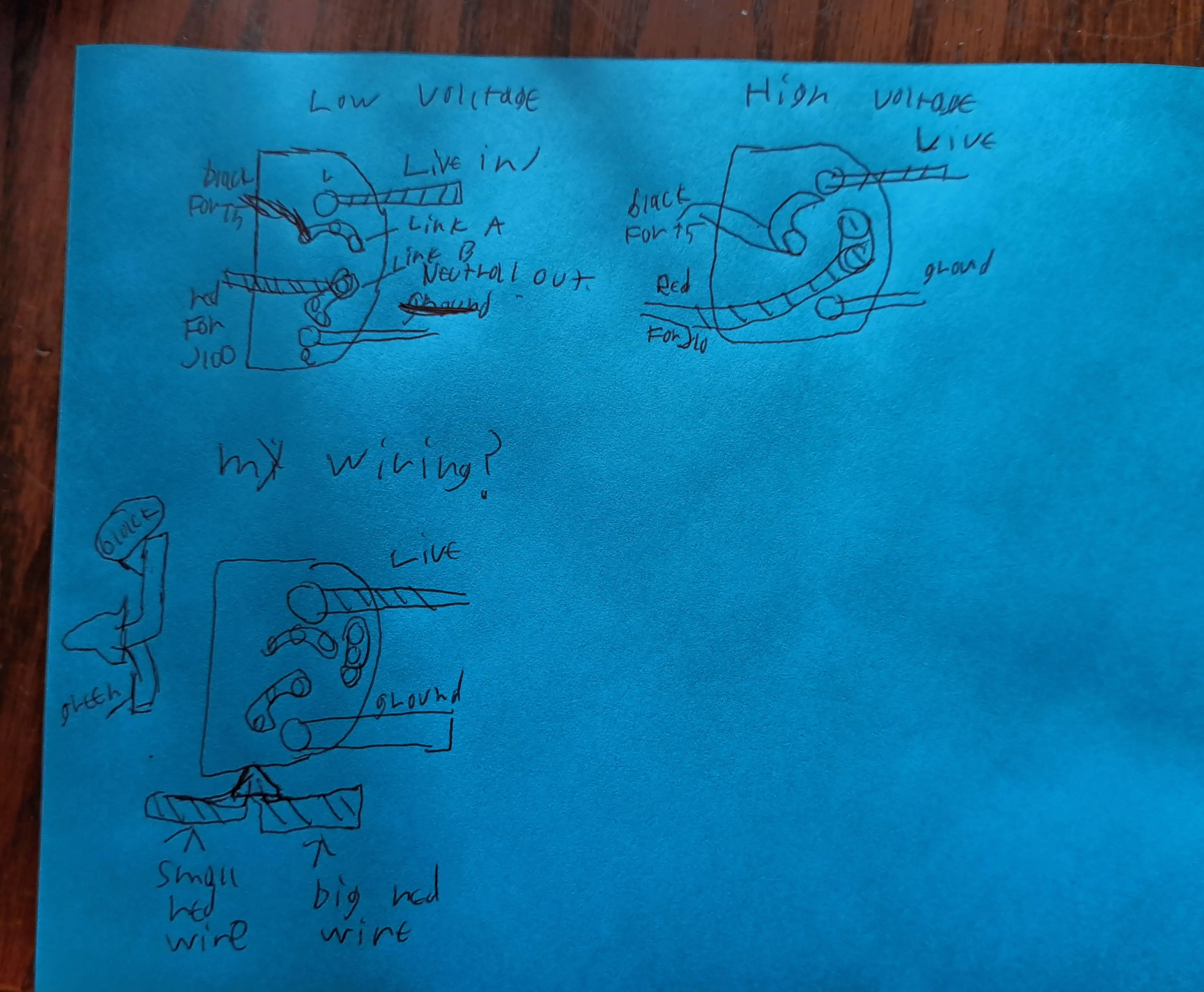

as-well as pictures of the original wiring and board

as-well as pictures of the original wiring and board